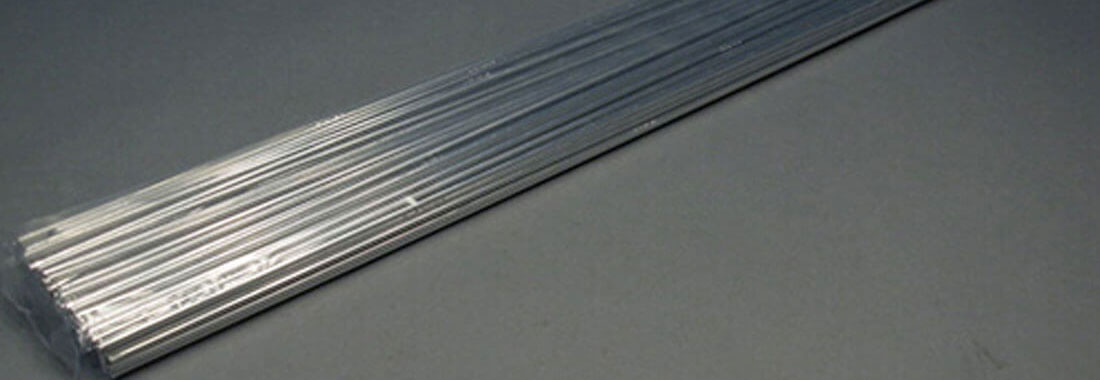

Stainless Steel ER-385 Filler Wires, SS ER-385 Filler Wires Supplier in Mumbai, India.

Bhansali Exports are one of the well known suppliers of Stainless Steel products such as Stainless Steel ER385 Filler Wire. We pride ourselves on quality, so we supply premium quality filler wires. SS ER385 filler wire is produced and designed to have high corrosion and mechanical properties. With this assurance of low prices and good service, you should consider us your preferred ER 385 filler wires supplier in Mumbai. Our products are produced to international quality standards and are employed in the petrochemicals, oil and gas power and chemical industries.

UNS N08904 filler wires are designed to give optimum performance in welding applications, demanding resistance to severe corrosive conditions. The ER-385 filler wire is in high demand due to its weldability and low usage complications, particularly TIG welding. We are one of the leading ER-385 TIG welding wire suppliers, and our products are reliable in their performance, making them suitable for use in important applications. We are committed to providing our clients with the highest quality of stainless steel ER-385 filler wires, focusing on innovation.

- Manufacturing Process Of Stainless Steel ER385 Filler Wires

- Specification Of SS ER385 TIG Wires

- Types Of Stainless Steel ER385 MIG Wire

- Other Types Of Stainless Steel ER385 Filler Wires

- Stainless Steel ER385 TIG Wire Equivalent Grades

- Chemical Composition of SS ER385 MIG Wires

- Mechanical Properties of SS ER385 Filler Wire

- SS ER385 Filler Wires Industrial Application

UNS N08904 Filler Wires, Stainless Steel ER-385 Filler Wires Stockist in India.

We supply materials to industries that require special and high-quality materials, including marine, automotive, and construction industries. Our SS ER-385 filler wires supplier services include support from our professional team to guarantee that the orders meet the needs of the clients. We are proud to supply the best quality of stainless steel ER-385 filler wires that improve weld quality as well as the efficiency of the industrial processes. Get the best stainless steel filler wire from us and enjoy the best quality and service.

Drawing and annealing

Extrusion

Rolling

Forming

| Standards | ASTM A580, A313, A555, A493 / ASME SA580, SA313, SA555, SA493, AMS 5514 |

| Form | MIG spools, TIG cut lengths, Reels and Coils |

| Type Of Welding | Inert Gas Welding |

| Current | MIG-DCEP / TIG-DCEN |

| Diameters | .023”, .030”, .035”, .045”, 1/16”, 3/32”, 1/8” |

| Standard TIG straight lengths are available | 36” (914 mm) or 39” (1000 mm) lengths. Other lengths available upon request. |

| AWS MIG & TIG Filler Metal Application & uses | Hardware tools, Metallurgy, Machinery, Construction, Shipbuilding, Petroleum, Chemical plant, Power sector, Gas Industry |

| Test Certificates | Wire Tensile Testing Wire Hardness Testing Metallographic Inspection / Investigation Corrosion Testing for Wire Chemical Analysis for Wire Alloy Verification Wire Wrap Testing Wire Elevated Temperature Testing Stress Rupture Testing (Creep) |

- SS ER385 Werkstoff Nr. 1.4842 Filler Wire

- AISI ER 385 Filler Wire

- ER 385 SS tig Wires

- Stainless Steel ER385 Filler Wire

- ER 385 Filler Wire

- AWS Class ER385 MIG Filler Metal Stock

- Stainless Steel ER 385 Filler Wire

- TIG Filler Wire Stainless Steel ER 385

- ASTM A580 Stainless Steel ER385 TIG Wires

- UNS S30888 Filler Wire

- SS ER-385 TIG Welding Wire

- SS ER385 MIG Industrial Wires

- Stainless Steel ER 385 Filler Wire

- Stainless Steel ER385 TIG Filler Wire

- Stainless Steel ER 385 MIG Wire

- Stainless Steel ER 385 TIG Wire

- ER385 ER Stainless Steel TIG Wire Price

- Stainless Steel ER 385 TIG Filler Wire

- ER385 ER Stainless Steel TIG Wire

- ER385 Stainless Steel TIG Wires

- ER385 Stainless Steel TIG Wire

- UNS S30888 Wires

- 1.4842 MIG Wire

- UNS S30888 MIG Wires

| Class | UNS | Oxford Alloys | SANDVIK | BOHLER | |

| ER385 | S30888 | Alloy 385 | EXATON 20.25.5.LCU | BOHLER THERMAINT 20/25 CU |

| C | Mn | Si | Cr | Ni | Mo | S | P | Cu | |

| Standard | ≤0.025 | 1.00-2.50 | ≤0.50 | 19.5-21.5 | 24.0-26.0 | 4.20-5.20 | ≤0.030 | ≤0.020 | 1.20-2.00 |

| Test | 0.013 | 1.93 | 0.21 | 20.5 | 25.10 | 4.67 | 0.003 | 0.012 | 1.69 |

| Tensile Strength (psi) | 86,000 psi (593 MPa) |

|---|---|

| Yield Strength (psi) | 57,000 psi (393 MPa) |

| Elongation (%) | 42% |

“ Check Bhansali Exports's offered stainless steel ER385 Filler/TIG/MIG Wires Prices, Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”