Inconel 718 Round Bar Stock, ASTM B637 Inconel Alloy 718 Bright Bars, Inconel UNS N07718 Round Bars, Alloy 718 Rods Supplier in Mumbai.

Bhansali Exports is a leading Inconel 718 Round Bars manufacturer and supplier for industries which offer quality products for global markets. Our focus is to serve quality Inconel 718 round bars for various industry applications as it surpasses the performance benchmarks in severe conditions. Our Inconel 718 round bars are reasonably priced and have relevant certifications like ISO. We supply various fields, including aerospace, marine, chemical processing, and power generation industries, due to the high strength and corrosion performance of Inconel 718.

Our Inconel 718 round bar manufacturers in India always provide these useful products for domestic and international customers. The bars come in several sizes and types, making them ideal for use in such items as turbines, their components, engines, nuclear reactors, and heat exchangers. With the best mechanical qualities, our Inconel 718 round bars can also support high temperatures, pressures, and fragile environments. These bars demonstrate very good fatigue characteristics and are very durable. In applications where failure is not an option, these bars are recommended.

- Manufacturing Process Of Inconel 718 Bars

- Specification Of Inconel 718 Round Bar

- Types Of Inconel Alloy 718 Bars

- Other Types Of Alloy 718 Bars

- Alloy 718 Bar Equivalent Grades

- Chemical Composition of Inconel Alloy 718 Bars

- Mechanical Properties of Inconel Alloy 718 Round Bar

- Inconel Alloy 718 Bars Industrial Application

718 Inconel Round Bar, Inconel DIN 2.4668 Hexagon Bars, Inconel Alloy 718 Forged Round Bar, ASME SB637 Inconel 718 Bars, ASTM B637 Inconel Alloy 718 Bars Exporter in India.

Being the leading Inconel 718 round bar manufacturers, we do more than just provide good products; we also offer good services. Our Inconel 718 round bars for sale have been tested thoroughly to meet international standards to give you long lasting service and value for your money. When you work with us, you will be guaranteed to benefit from the best products specialized for your industry and provided by a professional team. Make us your Nickel Alloy Inconel 718 round bar supplier and enjoy the best quality and customer relations.

In India, the availability of inconel 718 round bar suppliers ensures a steady inconel 718 round bar stock to meet diverse industrial needs. The inconel 718 round bar price varies depending on market fluctuations, alloy specifications, and the supplier's pricing policies. Customers benefit from competitive pricing strategies suppliers offer that maintain extensive inventories and efficient distribution networks. This accessibility enables industries to procure the exact quantities required without delays, ensuring continuity in production and project timelines.

Heating, rolling, and forming of reinforced steel bars

Quenching

Self-tempering & quality testing

Atmospheric cooling & finishing

| Specifications | ASTM B637 / ASME SB637 |

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Bar Diameter | 3 ~ 800mm |

| Hex Bar size | 2-100mm A/F |

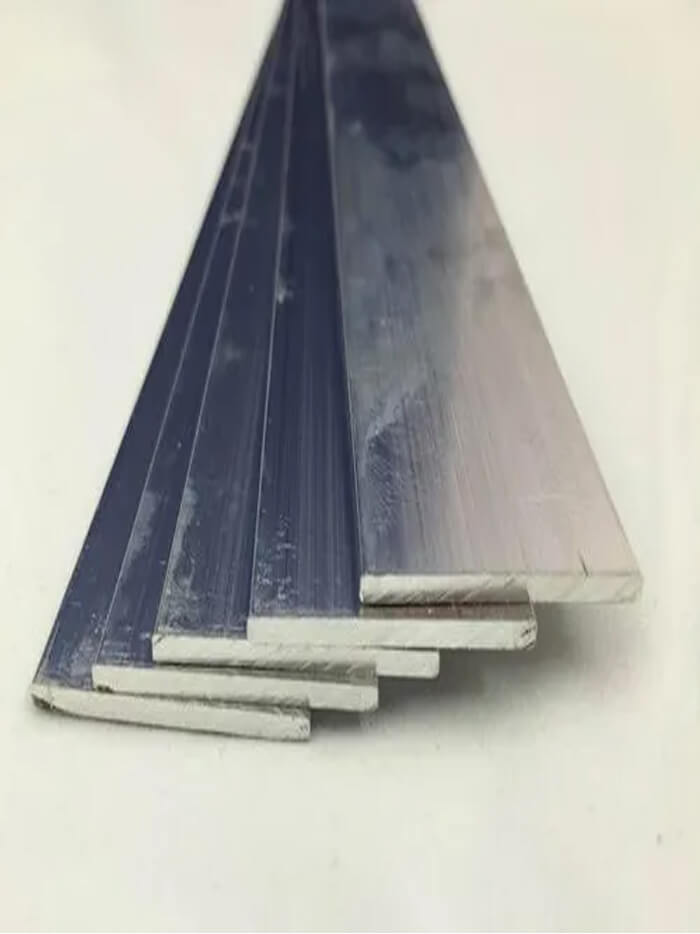

| Flat bar size | Thickness: 2 -100mm. Width: 10 to 500mm. |

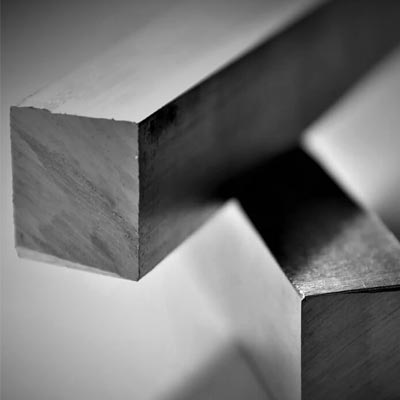

| Square bar size | 4 to 100mm |

| Rectangular Bars | Size: 33 x 30mm to 295 x 1066mm. Thickness: 3.0 to 12.0mm. |

| Hollow Bars | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Billet Size | 1/2 to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Rolled Bars Condition | Hardened & tempered, annealed |

| Cold Rolled Bar Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

- Inconel Alloy 718 Hexagonal Bar

- Alloy 718 Forged Bar

- ASTM B637 Nickel 718 Hex Bar

- Nickel Alloy 718 Half-Round Rods

- 718 Inconel Hot rolled Bar

- Inconel Alloy 718 Flat Bar

- ASTM B637 Inconel 718 Bar

- Alloy 718 Threaded Bar

- Inconel Alloy 718 Round Bar

- Nickel Alloy 718 Forged Rod

- UNS N07718 Round Bar

- Inconel 718 Round Bar Supplier

- Inconel Alloy 718 Hex Bar

- Inconel Alloy DIN 2.4668 Square bar

- Nickel Alloy 718 Square Bar

- Inconel 718 Round Bar

- Inconel Alloy 718 Hex Bar

- Nickel Alloy 2.4668 Round Bar

- UNS N07718 Bar

- ASME SB637 Alloy 718 Bar

- ASME SB637 Inconel 718 Bar

- Nickel 718 Bar

- Inconel Alloy 718 Bar Price

- ASTM B637 Inconel 718 Round Bar

- Inconel Alloy 718 Bars

- Inconel Alloy 718 Square Bar

- Inconel 718 Round Bar Suppliers

- Inconel Alloy N07718 Round Bars

- Inconel 2.4668 Round Bar Price

- Inconel Alloy 718 Rod Price Per Kg

- Alloy 2.4668 Round Bar

- Inconel 201 Bar

- ASTM B637 Nickel 718 Bar

- Alloy 718 Flat Bar

- Inconel 718 Round Bar Manufacturer

- ASTM B637 UNS N07718 Hex Bar

- Inconel 718 Flat Bar Stock

- Inconel Alloy 718 Round Bar

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 718 | 2.4668 | N07718 |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.30 max | – | 50.00 – 55.00 | 17.00 – 21.00 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 482 | 45 % |

“ Check Bhansali Exports's offered Inconel 718 bars Prices, Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”