ASTM B166 Inconel Alloy 601 Round Bars, ASTM B166 Inconel UNS N06600 Hexagon Bars, DIN 2.4816 Round Bar, Inconel 600 Round Bars Supplier in Mumbai.

Bhansali Exports is one of the prominent Inconel 600 round bar and Inconel 601 round bar exporters in India and worldwide. We take pride in its excellent Inconel 600 and 601 round bars responsive to various industries, including aerospace, chemical processing, and power generation industries. We are an authorized manufacturer of round bars in Inconel 600 and we assure you that our production is to the standards of the international market. Our price is also reasonable, and we offer the option of the size and finishing of the material to meet different client needs. We hold ISO and other quality assurance approvals to guarantee that our products are of premium quality and easily depended on.

As an Inconel 600 round bar exporter, our products target the domestic market while we are well-connected. Our Inconel 601 round bar exporter in India services are unique and customized to meet customers’ needs for product delivery and support across different industries. We take pride in being one of the prominent Inconel 600 round bar suppliers in India known for our focus on quality. Our round bars are developed with strong oxidation, high temperature and corrosion resistance features for tough working conditions.

- Manufacturing Process Of Inconel 600 Bars

- Specification Of Inconel 601 Round Bar

- Types Of Inconel Alloy 601 Bars

- Other Types Of Alloy 600 Bars

- Alloy 601 Bar Equivalent Grades

- Chemical Composition of Inconel Alloy 600 Bars

- Mechanical Properties of Inconel Alloy 601 Round Bar

- Inconel Alloy 601 Bars Industrial Application

Inconel 600 Bright Bar, 600 Inconel Rods, Inconel Alloy 600 Hex Bar, Alloy 601 Round Bar, UNS N06601 Round Bars, Inconel Alloy 600 Round Bar.

Our Inconel 600 and 601 round bars feature high strength, mechanical properties and weldability. These products are widely used in the petrochemical, marine and nuclear industries because they act at extremely low or high temperatures. As an Inconel 600 round bar exporter, we always focus on quality and service to offer our clients the best value for their money.

Heating, rolling, and forming of reinforced steel bars

Quenching

Self-tempering & quality testing

Atmospheric cooling & finishing

| Specifications | ASTM B166 / ASME SB166 |

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Bar Diameter | 3 ~ 800mm |

| Hex Bar size | 2-100mm A/F |

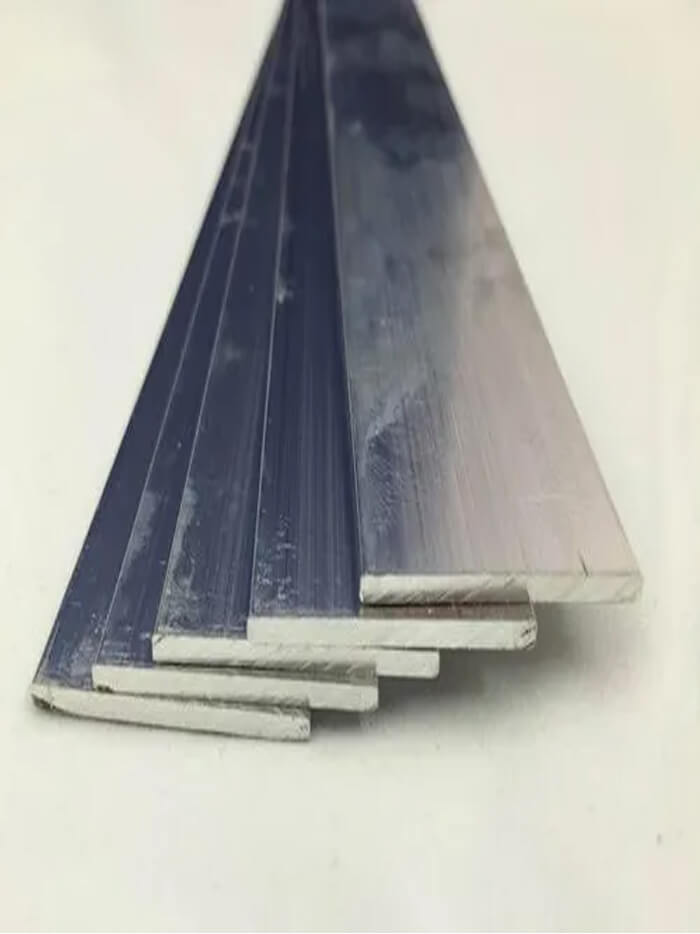

| Flat bar size | Thickness: 2 -100mm. Width: 10 to 500mm. |

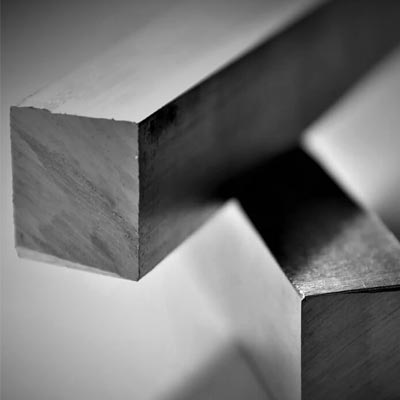

| Square bar size | 4 to 100mm |

| Rectangular Bars | Size: 33 x 30mm to 295 x 1066mm. Thickness: 3.0 to 12.0mm. |

| Hollow Bars | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Billet Size | 1/2 to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Rolled Bars Condition | Hardened & tempered, annealed |

| Cold Rolled Bar Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

- Inconel Alloy 600 Flat Bar

- Alloy 601 Forged Bar

- Nickel Alloy 600 Half-Round Rods

- ASTM B166 Nickel 601 Bar

- Inconel Alloy 600 Hex Bar

- Nickel Alloy 2.4816 Forged Rod

- Nickel 601 Round Bar

- Nickel Alloy 600 Hex Bar

- Nickel Alloy UNS N06600 Round Bar

- Alloy 600 Threaded Bar

- Nickel Alloy 601 Hexagonal Bar

- Nickel 600 Round Bar

- Nickel Alloy UNS N06601 Square bar

- DIN 2.4851 Bar

- ASTM B166 Nickel 600 Hex Bar

- Alloy 601 Round Bar

- Inconel 600 Rods

- UNS N06600 Round Bar

- Nickel 600 Bar

- ASME SB166 Alloy 601 Bar

- Nickel Alloy 600 Flat Bar

- Nickel Alloy 601 Round Bars

- Inconel Alloy 600 Square Bar

- Inconel Alloy 601 Bar Price

- ASTM B166 Nickel 600 Bar

- Nickel 601 Round Bar Suppliers

- ASTM B166 Inconel 600 Round Bar

- WNR 2.4851 Round Bar Price

- Inconel 601 Flat Bar Stock

- Alloy 2.4816 Round Bar

- Alloy 201 Bar

- Inconel Alloy 600 Bars

- Inconel 601 Round Bar Manufacturer

- Inconel Alloy 600 Rod Price Per Kg

- Nickel Alloy 601 Round Bar

- ASME SB166 Inconel 600 Bar

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

| C | Mn | Si | S | Cu | Fe | Ni | Cr |

| 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

“ Check Bhansali Exports's offered Inconel 600/601 bars Prices, Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”