Tantalum Round Bar, Tantalum Round Bar Supplier, Tantalum Round Bar Exporter, Tantalum Round Bar Supplier in Mumbai, Tantalum Round Bar Supplier in India.

Bhansali Exports is a top Tantalum bar manufacturer and supplier based in India that caters to different sectors. Our tantalum Round Bar is produced with the highest ASTM B365 standard. The Tantalum UNS R05200 Bars we offer are highly appreciated for their high strength, resistance to corrosion and toughness. Being a leading tantalum bar supplier, we offer tantalum round bars at reasonable prices to guarantee quality. Our round bars are certified and meet the required quality standards, which makes them reliable and efficient.

The tantalum round bar is used in many industries for its excellent heat and corrosion resistance. It is used in chemical processing, aerospace engineering, electronics and the manufacture of medical instruments. We are a reputable Tantalum Bar supplier, and our round bars are durable for high-temperature applications and resistant to chemicals. Whether you need tantalum for a significant medical tool or a rigid aerospace application component, the tantalum round bar will provide the necessary performance.

- Manufacturing Process Of Tantalum R05200 Bars

- Specification Of Tantalum R05400 Round Bar

- Types Of Tantalum R05255 Bars

- Other Types Of Tantalum R05252 Bars

- Tantalum R05240 Bar Equivalent Grades

- Chemical Composition of Tantalum R05200 Bars

- Mechanical Properties of Tantalum R05400 Round Bar

- Tantalum R05240 Bars Industrial Application

Tantalum Round Bar Exporter in Mumbai, Tantalum Round Bar Exporter in India, Tantalum Round Bar Manufacturer, Tantalum Round Bar Manufacturer in Mumbai.

Our tantalum bar prices are affordable without compromising quality. The tantalum round bar comes in different sizes and specifications to suit the client's needs. To produce the best quality Tantalum Bar, we have become one of India's top manufacturers and suppliers and export round bars to various countries.

Heating, rolling, and forming of reinforced steel bars

Quenching

Self-tempering & quality testing

Atmospheric cooling & finishing

| Specifications | ASTM B365/ ASME SB365 |

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Bar Diameter | 0.125" (3.18mm)~2.5" (63.5mm) |

| Hex Bar size | 2-100mm A/F |

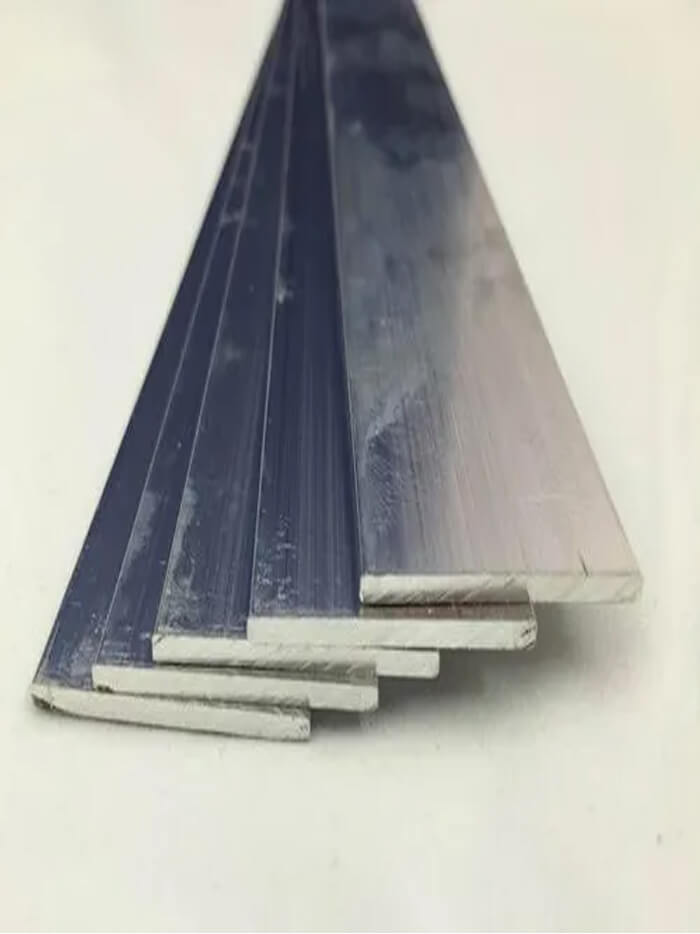

| Flat bar size | Thickness: 2 -100mm. Width: 10 to 500mm. |

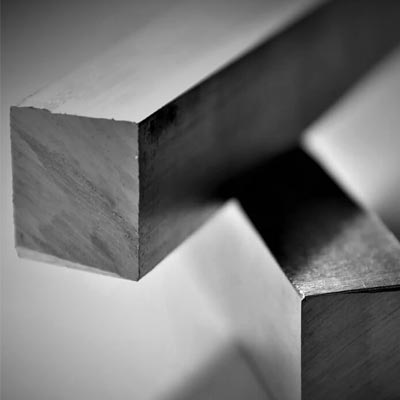

| Square bar size | 4 to 100mm |

| Rectangular Bars | Size: 33 x 30mm to 295 x 1066mm. Thickness: 3.0 to 12.0mm. |

| Hollow Bars | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Billet Size | 1/2 to 495mm Diameter |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients requirements |

| Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Rolled Bars Condition | Hardened & tempered, annealed |

| Cold Rolled Bar Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Form | Round, Rod, T-Bar, Channel Bar, Precision Ground Bar, Flat Bar, Square, Blocks, Round Rod, Rings, Hollow, Triangle, Rectangle, Hex (A/F), Threaded, Half Round Bar, Profiles, Billet, Ingot, I/H Bar, Forging etc. |

- ASME SB365 Tantalum Bar

- UNS R05252 Hexagonal Bar

- Tantalum Square Bar

- Tantalum Hexagonal Bar

- Tantalum Precision Ground Rod

- Tantalum R05200 T-Rod

- Tantalum Alloy R05400 Rectangular Bars

- UNS R05200 Round Bar

- UNS R05252 Rectangular Rod

- ASME SB365 Tantalum Forged Bar

- ASME SB365 Tantalum Rods

- Ta Alloy R05400 Square Barr

- Tantalum Hex Bar

- ASTM B365 Tantalum Bar

- UNS R05252 Tantalum Black Bar

- ASTM B365 Tantalum Round Bar

- ASTM B365 Tantalum Rods

- ASME SB365 Tantalum Half-Round Rods

- Tantalum R05400 Rods

- Ta Alloy Hot Rolled Bars

- Tantalum TA 1 Round Rod Suppliers

- ASME SB164 Tantalum TA 2 Round Rod

- Tantalum TA 1 Round Rod

- ASTM B365-12 Tantalum TA 2 Half-Round Rod

- Tantalum TA 1 Round Bar Suppliers

- Tantalum TA 2 Round Rod Manufacturer in India

| STANDARD UNS |

R05200 | R05400 | R05255 | R05252 | R05240 |

| Grade | C | O | N | H | Fe | Mo | Nb | Ni | Si | Ti | W |

| Tantalum | 0.01 max | 0.015 max | 0.01 | 0.0015 max | 0.01 max | 0.02 | 0.1 max | 0.01 max | 0.005 max | 0.01 | 0.05 |

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Tantalum | 16.6 g/cc | 3290 K, 2996°C, 5462°F | 285 M Pa (41 ksi) | 170 M Pa (25 ksi) | 30% |

“ Check Bhansali Exports's offered Tantalum bars Prices, Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”