Alloy C276 Rod manufacturer, ASTM B574 UNS N10276 Hex Bar, DIN 2.4819 Bar, Hastelloy c276 Square Bar, Hastelloy C276 Hex Bar, Hastelloy UNS N06022 Round Bars.

Bhansali Exports prides itself on being a leading manufacturer and supplier of high-quality Hastelloy C276 round bars, catering to various industries with precision-engineered solutions. We source the best quality Hastelloy C276 round bars, which offer excellent corrosion and high endurance capacity. Hastelloy C22 round bars also form part of our portfolio and are ideal for use in harsh conditions. Hastelloy round bar exporter, we offer a competitive price along with our products, which have been manufactured while maintaining international quality standards. Our products are certified to suit the industry standards, thus giving our clients a guarantee of their performance.

Our Hastelloy C276 round bars are used in many industries, such as chemical processing, oil and gas, aerospace and marine industries. They are built to last in harsh environments like high temperatures and highly corrosive environments and are therefore suitable for high-risk applications. As the leading Hastelloy C276 round bar suppliers, we ensure that our products are easily workable and can be formed to meet different manufacturing processes. In the present scenario, we are acknowledged as one of the leading Hastelloy C276 round bar exporters in the world.

- Manufacturing Process Of Hastealloy C22 Bars

- Specification Of Hastealloy C276 Round Bar

- Types Of Hastealloy Alloy C22 Bars

- Other Types Of Alloy C276 Bars

- Alloy C22 Bar Equivalent Grades

- Chemical Composition of Hastealloy Alloy C276 Bars

- Mechanical Properties of Hastealloy Alloy C22 Round Bar

- Hastealloy Alloy C276 Bars Industrial Application

UNS N06022 Round Bars, ASTM B574 UNS N06022 Flat Bar, Hastelloy C-22 Rod, C22 Hastelloy Bar Stock, Hastelloy DIN 2.4602 Bars, Hastelloy Alloy C22 Round Rod.

Being one of the most prominent Hastelloy round bar exporters, we guarantee that requirements of customers are fulfilled providing only high-quality bars. We have professional staff with a commitment to offer optimum service about delivery and support during procurement. Whether it is Hastelloy C276 round bars or Hastelloy C22 round bars, you can trust and rely on us for quality services. Whether you need a Hastelloy round bar for your engineering requirements or any other application, rely on us for the best products.

Heating, rolling, and forming of reinforced steel bars

Quenching

Self-tempering & quality testing

Atmospheric cooling & finishing

| Standard | ASTM B574/ ASME SB574 |

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

| Grade | C22, C22HS, C4, C2000 |

| Round Bars Length | 1 To 6 Meters, Custom Cut Length |

| Round Bar Thickness | 50 mm to 6000 mm Long |

| Round Bar Size | 3mm~ 800mm |

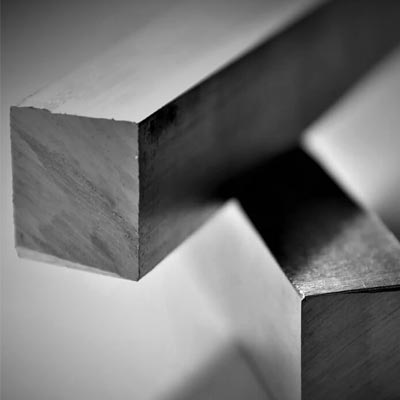

| Square Bar Size | 4mm* 4mm ~100mm* 100mm |

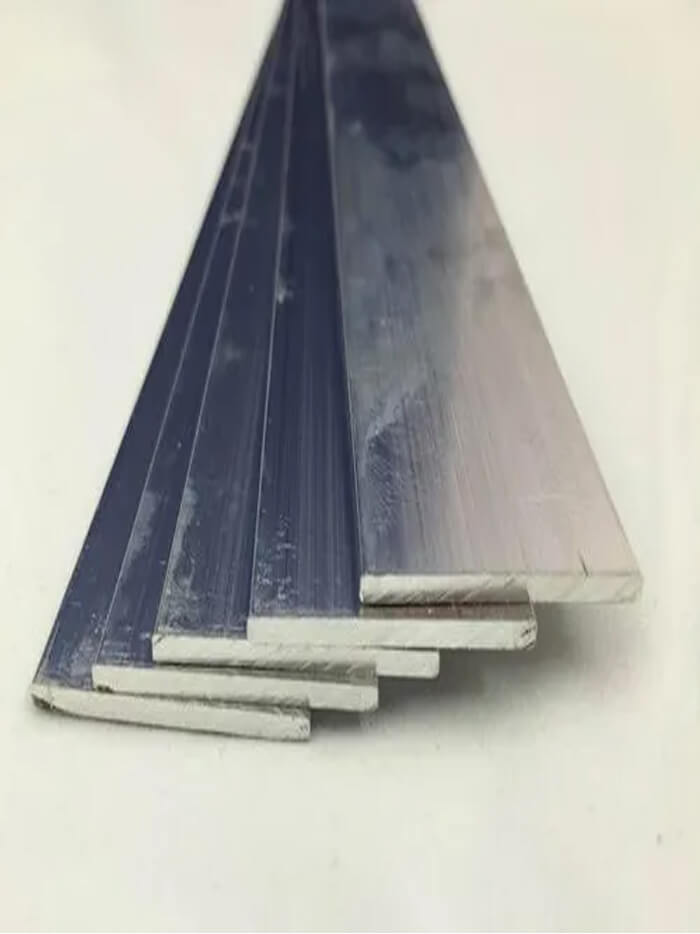

| Flat Bar Size | 2mm ~ 100mm |

| Hex Bar Size | 2mm ~ 100mm |

| Round Bars Type | Round Bar, Bright Bar, Square Bar, Hex Bar, Flat Bar, Forged Rod, Black Bar etc. |

- Alloy C2000 Round Bar

- Hastealloy Alloy UNS N06022 Round Bar

- ASTM B574 Hastealloy C276 Bar

- Alloy C22 Threaded Bar

- Hastealloy Alloy C4 Hex Bar

- Hastealloy C22 Rods

- Nickel C276 Round Bar

- Hastelloy C2000 Round Bar

- UNS N06455 Round Bar

- Hastelloy C4 Round Bar

- Alloy C276 Forged Bar

- Hastealloy Alloy C276 Hexagonal Bar

- Alloy C22 Hex Bar manufacturer in India

- Hastealloy Alloy UNS N07022 Square bar

- Hastealloy Alloy C22 Flat Bar

- Hastelloy C4 Round Bar

- Hastealloy Alloy C22 Half-Round Rods

- Hastelloy C22 ASTM B574 Flat Bar

- Nickel Alloy 2.4602 Hex Bar

- Hastealloy Alloy 2.4610 Forged Rod

- Hastelloy C276 Hex Bar

- ASTM B574 Nickel N06200 Hex Bar

- DIN 2.4675 Bar

- Hastealloy C2000 Flat Bar Stock

- Hastealloy Alloy UNS N06022 Flat Bar

- Hastelloy C276 Round Bar Suppliers

- Hastealloy Alloy C276 Round Bar

- Hastealloy C2000 Round Bar Manufacturer

- Hastelloy B574 Hollow Bar

- Nickel Alloy N06455 Bar Price

- Hastelloy C4 Square Bar

- ASME SB574 Hastealloy C22 Bar

- Nickel Alloy C22 Square Bar

- UNS N06455 Hastelloy C276 Hex Bar

- ASTM B574 Hastealloy 2.4375 Bar

- Hastelloy C22 Grade Square Bar

- Hastealloy C2000 Bar

- WNR 2.4602 Round Bar Price

- Hastealloy Alloy UNS N07022 Round Bars

- Hastelloy C4 Welding Rod

- Hastealloy 2.4675 Round Bar Suppliers

- Alloy 201 Bar

- ASME SB574 Alloy C4 Bar

- Hastealloy Alloy C22 Rod Price Per Kg

- ASTM B574 Hastealloy C22 Round Bar

- Hastealloy Alloy N06200 Bars

| STANDARD | WERKSTOFF NR. | UNS | GOST | AFNOR | JIS | OR | EN |

|---|---|---|---|---|---|---|---|

| Hastelloy C22 | 2.4602 | N06022 | - | - | NW 6022 | - | NiCr21Mo14W |

| Hastelloy C4 | 2.4610 | N06455 | |||||

| Hastelloy C-22HS | - | N07022 | |||||

| Hastelloy C2000 | 2.4675 | N06200 |

| Grade | Ni | C | Cr | Co | Fe | Mn | Mo | P | Si | S | W | V |

| Hastelloy C22 / C22HS | Bal | 0.010 max | 20 – 22.5 | 2.5 max | 2 – 6 | 0.50 max | 12.5 – 14.5 | 0.02 max | 0.08 max | 0.02 max | 2.5 – 3.5 | 0.35 max |

| Hastelloy C4 | 65.0 min | 0.01 max | 14 - 18 | 2.0 max | 3.0 max | 1.0 max | 14 - 17 | - | 0.08 max | - | - | - |

| Hastelloy C2000 | Bal | - | 22.00-24.00 | - | 3.00 max. | - | 15.00-17.00 | - | - | - | - | - |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.69 g/cm3 | 1399 °C (2550 °F) | Psi – 1,00,000 , MPa – 690 | Psi – 45000 , MPa – 310 | 45 % |

| Hastelloy C276 | Ni | C | Mo | Mn | Si | Fe | P | S | Co | Cr |

| Balance | 0.01 max | 15 – 17 | 1.0 max | 0.08 max | 4 – 7 | 0.04 max | 0.03 max | 2.5 max | 14.5 – 16.5 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 52,000 , MPa – 355 | Psi – 1,15,000 , MPa – 790 | 40 % |

| Sr. No | Hastelloy C276 | Ex-Works | CIF Price | Stock |

| 1 | 20mm to 50mm | $ 53.25/kg | $ 54.25/kg | Ex-Stock |

| 2 | 50mm to 70mm | $ 53.50/kg | $ 54.20/kg | Ex-Stock |

| 3 | 70mm to 100mm | $ 53.50/kg | $ 54.20/kg | Ex-Stock |

| 4 | 100mm + | $ 55.25/kg | $ 56.75/kg | Ex-Stock |

| CD | Cold drawn | P | Polished |

| BD | Bright drawn | SRE | Slit rolled edge |

| CG | Centreless ground | HF | Hot finished |

| CF | Cold finished | HRAP | Hot rolled annealed and pickled |

| P&T | Peeled and turned | RT | Rough turned/peeled |

| ST | Smooth turned | PR | Peeled and reeled |

| C276 Hastelloy Rectangular Bar Cold Drawn | Hastelloy C276 N10276 Polished Square Bar |

| Alloy C276 UNS N10276 Square Bar Black | C276 UNS N10276 Black Bar |

| C276 UNS N10276 Square Bar | Hastelloy C-276 UNS N10276 Polished Flat Bar |

| Hastelloy Alloy C276 Rectangular Bar Black | Hastelloy C276 B574 Bright Bar Hex |

| Hastelloy C276 Square Bar Bright | Alloy C276 UNS N10276 Bright Bar Cold Drawn |

| Hastelloy C-276 UNS N10276 Rectangular Bar stock | Hastelloy C276 UNS N10276 Polished Bar Stock |

| Hastelloy C276 B574 Square Bar Annealed | Hastelloy B574 Bright Bar Flat |

| Hastelloy C276 N10276 Hex Bar Cold Drawn | Alloy C276 Hastelloy Triangular Bar |

| Alloy C276 Hastelloy Rectangular Bar Polished | ASTM B574 Hastelloy UNS N10276 Polished Round Bar |

| Alloy C276 Hastelloy Threaded Bar M16 | Hastelloy C276 Threaded Rods |

| Hastelloy C276 Grade Hex Bar Black | Hastelloy C276 B574 Square Rod |

| Hastelloy C276 Alloy Rectangular Bar Bright | Hastelloy Alloy C276 Bright Bar Hollow |

| Hastelloy C276 Alloy Threaded Bar M12 | Hastelloy C276 Grade Threaded Bar Stock |

| Metric | US Bar | ASTM/ Canadian | Japanese | ||||

|---|---|---|---|---|---|---|---|

| Bar Size | Diam. (mm) | Bar Size | Diam. (Inch) | Bar Size | Diam. (mm2) | Bar Size | Diam. (mm) |

| 5 | 5 | #2 | 0.250 | 10M | 100 | 6 | 6 |

| 5.5 | 5.5 | #3 | 0.375 | 15M | 200 | 10 | 10 |

| 6 | 6 | #4 | 0.500 | 20M | 300 | 13 | 13 |

| 7 | 7 | #5 | 0.625 | 25M | 500 | 16 | 16 |

| 8 | 8 | #6 | 0.750 | 30M | 700 | 19 | 19 |

| 9 | 9 | #7 | 0.875 | 35M | 1000 | 22 | 22 |

| 10 | 10 | #8 | 1.000 | 45M | 1500 | 25 | 25 |

| 11 | 11 | #9 | 1.125 | 55M | 2500 | 29 | 29 |

| 12 | 12 | #10 | 1.250 | 32 | 32 | ||

| 14 | 14 | #11 | 1.375 | 35 | 35 | ||

| 16 | 16 | #12 | 1.500 | 38 | 38 | ||

| 18 | 18 | #13 | 1.625 | 41 | 41 | ||

| 20 | 20 | #14 | 1.750 | 44 | 44 | ||

| 22 | 22 | #15 | 1.875 | 48 | 48 | ||

| 25 | 25 | #16 | 2.000 | 51 | 51 | ||

| 28 | 28 | #18 | 2.250 | 57 | 57 | ||

| 32 | 32 | ||||||

| 36 | 36 | ||||||

| 40 | 40 | ||||||

| 44 | 44 | ||||||

| 50 | 50 | ||||||

| Element | Hastelloy C276 |

| Melting Point | 1370 °C (2500 °F) |

|

Nickel Alloy C 276 – Round

*CG – Centerless Ground RT – Hot Rolled and Rough Turned |

1/4 CG 3/8 CG 1/2 CG 5/8 CG 3/4 CG 7/8 CG | 1 CG 1-1/8 CG 1-1/4 CG 1-1/2 CG 1-3/4 CG 2 CG | 2-1/4 CG 2-1/2 CG 2-3/4 CG 3 CG 3-1/2 RT 4 RT |

|

Alloy |

Product form |

Dimension |

| ALLOY C-276 AMS 5750 (Ni/15Cr/16Mo/4W) | Rod; cold drawn, pickled, soft annealed | Dia=6.0 mm, Weight=0.25 kg/m |

| Rod; solution annealed, ground, polished | Dia=8.0 mm, Weight=0.44 kg/m | |

| Rod; solution annealed, ground, polished | Dia=10.0 mm, Weight=0.7 kg/m | |

| Rod; hot finished, ground, solution annealed | Dia=12.0 mm, Weight=1.01 kg/m | |

| Rod; hot rolled, solution annealed | Dia=12.7 mm, Weight=1.13 kg/m | |

| Rod; hot finished, solution annealed | Dia=16.0 mm, Weight=1.8 kg/m | |

| Rod; solution annealed, peeled | Dia=20.0 mm, Weight=2.85 kg/m | |

| Rod; hot finished, solution annealed, peeled | Dia=25.4 mm, Weight=4.5 kg/m | |

| Rod; hot worked, solution annealed, peeled | Dia=30.0 mm, Weight=6.1 kg/m | |

| Rod; hot rolled, solution annealed | Dia=31.8 mm, Weight=7.05 kg/m | |

| Rod; Machined, Solution annealed | Dia=35.0 mm, Weight=7.95 kg/m | |

| Rod; hot rolled, solution annealed, machined | Dia=40.0 mm, Weight=11.3 kg/m | |

| Rod; hot worked, solution annealed, peeled | Dia=45.0 mm, Weight=14.15 kg/m | |

| Rod; annealed, peeled | Dia=50.8 mm, Weight=18.0 kg/m | |

| Rod; hot rolled, sol annealed, machined | Dia=55.0 mm, Weight=21.0 kg/m | |

| Rod; hot finished, solution annealed, peeled | Dia=60.0 mm, Weight=26.0 kg/m | |

| Rod; hot finished, solution annealed, peeled | Dia=63.5 mm, Weight=28.0 kg/m | |

| Rod; hot worked, solution annealed, peeled | Dia=70.0 mm, Weight=35.0 kg/m | |

| Rod; hot finished, solution annealed, peeled | Dia=80.0 mm, Weight=45.2 kg/m | |

| Rod; hot finished, solution annealed, peeled | Dia=88.9 mm, Weight=57.0 kg/m | |

| Rod; peeled, sol annealed | Dia=90.0 mm, Weight=57.3 kg/m | |

| Rod; forged, peeled, annealed | Dia=101.6 mm, Weight=70.9 kg/m | |

| Round; hot finished, peeled | Dia=105.0 mm, Weight=73.3 kg/m | |

| Round; solution annealed, peeled | Dia=115.0 mm, Weight=92.3 kg/m | |

| Rod; forged, annealed, peeled | Dia=130.0 mm, Weight=118 kg/m | |

| Rod; forged, solution annealed, turned | Dia=160.0 mm, Weight=180 kg/m | |

| Rod; forged, solution annealed, turned | Dia=180.0 mm, Weight=226.2 kg/m | |

| Rod; forged, turned | Dia=203.2 mm, Weight=288 kg/m | |

| Rod; forged, solution annealed, turned | Dia=230.0 mm, Weight=369.4 kg/m | |

| Rod; hot rolled, solution annealed, turned | Dia=250.0 mm, Weight=436.4 kg/m |

| Metric system: standard length is | 9 - 12 metres |

| USA | 40 feet |

| H&T | Hardened and tempered. |

| ANN | Annealed |

| PH | Precipitation hardened. |

| Round Bar | ||||||||

|---|---|---|---|---|---|---|---|---|

| Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr | Size | Kgs / Foot | Kgs / Mtr |

| 3mm | 0.017 | 0.055 | 20mm | 0.753 | 2.470 | 3″ | 10.900 | 35.762 |

| 1/8″ | 0.019 | 0.062 | 22mm | 0.908 | 2.979 | 3-1/4″ | 12.800 | 41.996 |

| 5/32″ | 0.029 | 0.095 | 7/8″ | 0.926 | 3.038 | 3-1/2″ | 14.850 | 48.772 |

| 4mm | 0.030 | 0.098 | 24mm | 1.080 | 3.543 | 3-3/4″ | 17.001 | 55.780 |

| 3/16″ | 0.043 | 0.141 | 25mm | 1.180 | 3.871 | 4″ | 19.306 | 63.340 |

| 5mm | 0.047 | 0.154 | 1″ | 1.210 | 3.970 | 4-1/4″ | 21.908 | 72.249 |

| 7/32″ | 0.058 | 0.190 | 26mm | 1.271 | 4.170 | 4-1/2″ | 24.4487 | 80.340 |

| 6mm | 0.068 | 0.223 | 27mm | 1.368 | 4.490 | 4-3/4″ | 27.366 | 90.249 |

| 1/4″ | 0.076 | 0.249 | 1-1/8″ | 1.534 | 5.033 | 5″ | 30.461 | 99.940 |

| 7mm | 0.091 | 0.298 | 30mm | 1.691 | 5.548 | 5-1/2″ | 36.690 | 121.000 |

| 5/16″ | 0.118 | 0.387 | 1-1/4″ | 1.924 | 6.349 | 6″ | 43.860 | 143.900 |

| 8mm | 0.120 | 0.398 | 32mm | 1.894 | 6.314 | 6-1/2″ | 51.093 | 167.630 |

| 9mm | 0.152 | 0.498 | 1-3/8″ | 2.303 | 7.550 | 7″ | 59.432 | 196.000 |

| 3/8″ | 0.170 | 0.557 | 35mm | 2.390 | 7.553 | 7-1/2″ | 68.226 | 225.000 |

| 10mm | 0.189 | 0.620 | 36mm | 2.438 | 7.999 | 8″ | 77.586 | 254.55 |

| 11mm | 0.228 | 0.748 | 38mm | 2.792 | 8.903 | 10″ | 121.048 | 397.140 |

| 7/16″ | 0.232 | 0.761 | 1-1/2″ | 2.715 | 8.951 | |||

| 12mm | 0.271 | 0.889 | 40mm | 3.009 | 9.872 | |||

| 1/2″ | 0.303 | 0.994 | 1-5/8″ | 3.200 | 10.449 | |||

| 13mm | 0.318 | 1.043 | 1-3/4″ | 3.712 | 12.179 | |||

| 14mm | 0.368 | 1.207 | 45mm | 3.807 | 12.555 | |||

| 9/16″ | 0.383 | 1.256 | 1-7/8″ | 4.260 | 13.977 | |||

| 15mm | 0.424 | 1.391 | 48mm | 4.330 | 14.205 | |||

| 5/8″ | 0.473 | 1.551 | 50mm | 4.698 | 15.414 | |||

| 16mm | 0.481 | 1.578 | 2″ | 4.848 | 15.906 | |||

| 17mm | 0.543 | 1.791 | 2-1/8″ | 5.475 | 17.963 | |||

| 11/16″ | 0.573 | 1.880 | 2-1/4″ | 6.135 | 20.128 | |||

| 18mm | 0.610 | 2.001 | 60mm | 6.768 | 22.205 | |||

| 3/4″ | 0.682 | 2.237 | 2-3/8″ | 6.838 | 22.435 | |||

| 2-1/2″ | 7.576 | 24.856 | ||||||

| 2-5/8″ | 8.354 | 27.409 | ||||||

| 2-3/4″ | 9.169 | 30.083 | ||||||

| Element | Hastelloy C276 |

| Density | 8.89 g/cm3 |

| Melting Point | 1370 °C (2500 °F) |

| Tensile Strength | Psi – 1,15,000 , MPa – 790 |

| Yield Strength (0.2%Offset) | Psi – 52,000 , MPa – 355 |

| Elongation | 40 % |

| Hardness (Brinell) | - |

|

Hastelloy C276 Flat bar – metric sizes and

weights

|

|||

|---|---|---|---|

|

Flat Size

|

KG’s per Metre

|

Standard Length (metres)

|

Colour Code

|

|

10 x 3

|

0.24

|

6.0

|

Blue

|

|

13 x 3

|

0.31

|

6.0

|

Blue

|

|

13 x 5

|

0.46

|

6.0

|

Orange

|

|

16 x 3

|

0.38

|

6.0

|

Blue

|

|

16 x 5

|

0.64

|

6.0

|

Orange

|

|

16 x 8

|

1.03

|

6.0

|

Red

|

|

20 x 3

|

0.48

|

6.0

|

Blue

|

|

20 x 5

|

0.81

|

6.0

|

Orange

|

|

20 x 6

|

0.97

|

6.0

|

White

|

|

20 x 10

|

1.61

|

6.0

|

Yellow

|

|

25 x 3

|

0.60

|

6.0

|

Blue

|

|

25 x 5

|

1.01

|

6.0

|

Orange

|

|

25 x 6

|

1.21

|

6.0

|

White

|

|

25 x 8

|

1.61

|

6.0

|

Red

|

|

25 x 10

|

2.01

|

6.0

|

Yellow

|

|

25 x 12

|

2.41

|

6.0

|

Pink

|

|

32 x 3

|

0.77

|

6.0

|

Blue

|

|

32 x 5

|

1.29

|

6.0

|

Orange

|

|

32 x 6

|

1.55

|

6.0

|

White

|

|

32 x 8

|

2.06

|

6.0

|

Red

|

|

32 x 10

|

2.58

|

6.0

|

Yellow

|

|

32 x 12

|

3.09

|

6.0

|

Pink

|

|

40 x 3

|

0.97

|

6.0

|

Blue

|

|

40 x 5

|

1.61

|

6.0

|

Orange

|

|

40 x 6

|

1.93

|

6.0

|

White

|

|

40 x 8

|

2.58

|

6.0

|

Red

|

|

40 x 10

|

3.22

|

6.0

|

Yellow

|

|

40 x 12

|

3.86

|

6.0

|

Pink

|

|

40 x 16

|

5.15

|

6.0

|

Grey

|

|

40 x 20

|

6.14

|

6.0

|

Green

|

|

50 x 3

|

1.21

|

6.0

|

Blue

|

|

50 x 5

|

2.01

|

6.0

|

Orange

|

|

50 x 6

|

2.41

|

6.0

|

White

|

|

50 x 8

|

3.22

|

6.0

|

Red

|

|

50 x 10

|

4.02

|

6.0

|

Yellow

|

|

50 x 12

|

4.83

|

6.0

|

Pink

|

|

50 x 16

|

6.44

|

6.0

|

Grey

|

|

50 x 20

|

8.05

|

6.0

|

Green

|

|

50 x 25

|

10.1

|

6.0

|

Purple

|

|

65 x 3

|

1.57

|

6.0

|

Blue

|

|

65 x 5

|

2.62

|

6.0

|

Orange

|

|

65 x 6

|

3.14

|

6.0

|

White

|

|

65 x 8

|

4.18

|

6.0

|

Red

|

|

65 x 10

|

5.23

|

6.0

|

Yellow

|

|

65 x 12

|

6.28

|

6.0

|

Pink

|

|

65 x 16

|

8.37

|

6.0

|

Grey

|

|

65 x 20

|

10.5

|

6.0

|

Green

|

|

65 x 25

|

13.1

|

6.0

|

Purple

|

|

75 x 5

|

3.02

|

6.0

|

Orange

|

|

75 x 6

|

3.62

|

6.0

|

White

|

|

75 x 8

|

4.83

|

6.0

|

Red

|

|

75 x 10

|

6.04

|

6.0

|

Yellow

|

|

75 x 12

|

7.24

|

6.0

|

Pink

|

|

75 x 16

|

9.66

|

6.0

|

Grey

|

|

75 x 20

|

12.1

|

6.0

|

Green

|

|

75 x 25

|

15.1

|

6.0

|

Purple

|

|

75 x 40

|

24.1

|

6.0

|

Yellow

|

|

90 x 5

|

3.62

|

6.0

|

Orange

|

|

90 x 6

|

4.35

|

6.0

|

White

|

|

90 x 8

|

5.79

|

6.0

|

Red

|

|

90 x 10

|

7.24

|

6.0

|

Yellow

|

|

90 x 12

|

8.69

|

6.0

|

Pink

|

|

100 x 5

|

4.02

|

6.0

|

Orange

|

|

100 x 6

|

4.83

|

6.0

|

White

|

|

100 x 8

|

6.44

|

6.0

|

Red

|

|

100 x 10

|

8.05

|

6.0

|

Yellow

|

|

100 x 12

|

9.66

|

6.0

|

Pink

|

|

100 x 16

|

12.9

|

6.0

|

Grey

|

|

100 x 20

|

16.1

|

6.0

|

Green

|

|

100 x 25

|

20.1

|

6.0

|

Purple

|

|

100 x 50

|

40.2

|

6.0

|

Green

|

|

110 x 6

|

5.31

|

6.0

|

White

|

|

110 x 8

|

7.08

|

6.0

|

Red

|

|

110 x 10

|

8.85

|

6.0

|

Yellow

|

|

110 x 12

|

10.6

|

6.0

|

Pink

|

|

130 x 5

|

5.23

|

6.0

|

Orange

|

|

130 x 6

|

6.28

|

6.0

|

White

|

|

130 x 8

|

8.37

|

6.0

|

Red

|

|

130 x 10

|

10.5

|

6.0

|

Yellow

|

|

130 x 12

|

12.6

|

6.0

|

Pink

|

|

130 x 16

|

16.7

|

6.0

|

Grey

|

|

130 x 20

|

20.9

|

6.0

|

Green

|

|

130 x 25

|

26.2

|

6.0

|

Purple

|

|

150 x 5

|

6.04

|

6.0

|

Orange

|

|

150 x 6

|

7.24

|

6.0

|

White

|

|

150 x 8

|

9.66

|

6.0

|

Red

|

|

150 x 10

|

12.1

|

6.0

|

Yellow

|

|

150 x 12

|

14.5

|

6.0

|

Pink

|

|

150 x 16

|

19.3

|

6.0

|

Grey

|

|

150 x 20

|

24.1

|

6.0

|

Green

|

|

150 x 25

|

30.1

|

6.0

|

Purple

|

|

150 x 50

|

60.4

|

6.0

|

Green

|

|

180 x 5

|

7.24

|

6.0

|

Orange

|

|

180 x 6

|

8.69

|

6.0

|

White

|

|

180 x 10

|

14.5

|

6.0

|

Yellow

|

|

180 x 12

|

17.4

|

6.0

|

Pink

|

|

180 x 16

|

23.2

|

6.0

|

Grey

|

|

180 x 20

|

29.0

|

6.0

|

Green

|

|

180 x 25

|

36.2

|

6.0

|

Purple

|

|

200 x 6

|

9.66

|

6.0

|

White

|

|

200 x 8

|

12.9

|

6.0

|

Red

|

|

200 x 10

|

16.1

|

6.0

|

Yellow

|

|

200 x 12

|

19.3

|

6.0

|

Pink

|

|

200 x 16

|

25.7

|

6.0

|

Grey

|

|

200 x 20

|

32.2

|

6.0

|

Green

|

|

200 x 25

|

40.3

|

6.0

|

Purple

|

|

250 x 6

|

12.1

|

6.0

|

White

|

|

250 x 8

|

16.1

|

6.0

|

Red

|

|

250 x 10

|

20.1

|

6.0

|

Yellow

|

|

250 x 12

|

24.1

|

6.0

|

Pink

|

|

250 x 16

|

32.2

|

6.0

|

Grey

|

|

250 x 20

|

40.2

|

6.0

|

Green

|

|

250 x 25

|

50.3

|

6.0

|

Purple

|

|

300 x 6

|

14.5

|

6.0

|

White

|

|

300 x 8

|

19.3

|

6.0

|

Red

|

|

300 x 10

|

24.1

|

6.0

|

Yellow

|

|

300 x 12

|

29.0

|

6.0

|

Pink

|

|

300 x 16

|

38.6

|

6.0

|

Grey

|

|

300 x 20

|

48.3

|

6.0

|

Green

|

|

300 x 25

|

60.4

|

6.0

|

Purple

|

- Railway engines and coaches

- For manufacturing gears, bearings, and hinges

- Used for automobile industries to make nuts, bolts, shafts

- Heavy engineering industries

- Manufacturing conveyor shafts

- To produce cold headed components

- Used for electric pumps/motors

- To making arms and ammunition

- Textile industry

- Used in agricultural sector

| Tolerances for Cold Drawn Hastelloy C276 Round Bar | ||

|---|---|---|

| Shape / Section | Size, diameter or width across flats | Permitted variation |

| mm | mm | |

| Round | ≥6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 100 |

+ 0 to – 0.070 + 0 to – 0.085 + 0 to – 0.100 + 0 to – 0.120 + 0 to – 0.140 |

| Flat (thickness) | < 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 |

+ 0 to – 0.110 + 0 to – 0.130 + 0 to – 0.250 + 0 to – 0.350 |

| Flat (width) | < 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 100 > 100 ≦ 130 > 130 ≦ 160 > 160 ≦ 320 |

+ 0 to – 0.110 + 0 to – 0.130 + 0 to – 0.160 + 0 to – 0.190 + 0 to – 0.220 + 0 to – 0.350 + 0 to – 1.00 + 1.00 to – 1.00 |

| Square and hexagon |

≥ 6 ≦ 18 > 18 ≦ 30 > 30 ≦ 50 > 50 ≦ 80 > 80 ≦ 105 |

+ 0 to – 0.090 + 0 to – 0.110 + 0 to – 0.130 + 0 to – 0.160 + 0 to – 0.250 |

- Hot Working

- Machining

- Heat Resistance

- Heat Treatment

- Cold Working

- Welding

- Fabrication

| Element | Hastelloy C276 |

| Density | 8.89 g/cm3 |

- Highly controlled heat treatment with SCADA control

- Certified to all major international specs

- Precision Straightened

- Available in shape of Round Bars | Hex | Square

- Precision Tolerance

- Unique Packaging

- Close Length Tolerance

- Mirror Finish

|

hex bar Size in Inches

|

hex bar Wt per Ft

|

hex bar Wt per 12′

|

|---|---|---|

|

3/16″

|

0.104

|

1.248

|

|

1/4″

|

0.180

|

2.160

|

|

5/16″

|

0.290

|

3.480

|

|

3/8″

|

0.C276

|

4.920

|

|

7/16″

|

0.560

|

6.72

|

|

1/2″

|

0.740

|

8.880

|

|

9/16″

|

0.930

|

11.16

|

|

5/8″

|

1.150

|

13.80

|

|

11/16″

|

1.390

|

16.68

|

|

3/4″

|

1.660

|

19.92

|

|

13/16″

|

1.950

|

23.40

|

|

7/8″

|

2.300

|

27.60

|

|

15/16″

|

2.600

|

31.20

|

|

1″

|

2.90

|

34.80

|

|

1-1/16″

|

3.30

|

39.60

|

|

1-1/8″

|

3.700

|

44.40

|

|

1-1/4″

|

4.600

|

55.20

|

|

1-5/16″

|

5.100

|

61.20

|

|

1-3/8″

|

5.600

|

67.20

|

|

1-7/16″

|

6.100

|

73.20

|

|

1-1/2″

|

6.600

|

79.20

|

|

1-5/8″

|

7.800

|

93.60

|

|

1-3/4″

|

9.030

|

108.36

|

|

1-7/8″

|

10.400

|

124.80

|

|

2″

|

11.80

|

141.60

|

|

2-1/4″

|

14.920

|

179.04

|

|

2-3/8″

|

16.920

|

203.04

|

|

2-1/2″

|

18.42

|

221.04

|

|

3″

|

26.53

|

318.36

|

“ Check Bhansali Exports's offered Hastealloy C22/C276 bars Prices, Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”