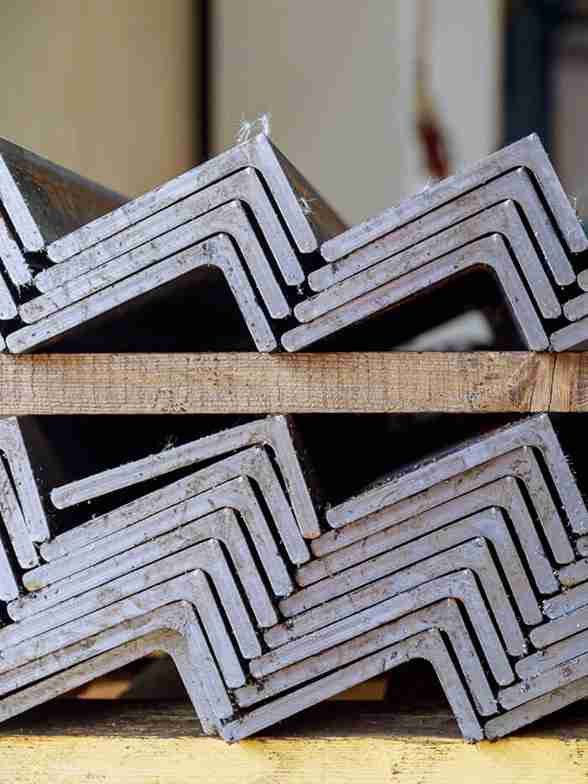

When it comes to strength, durability, and corrosion resistance, stainless steel is the ultimate material. Among the many types of stainless steel alloys available, two popular ones are 17-4ph and 15-5ph. These alloys bring a unique combination of properties ideal for various industrial applications. One of the most significant uses of these alloys is in constructing angles and flats.

Stainless Steel 17-4ph Angles Features

Stainless steel 17-4ph angles are popular for mechanical and structural applications due to their excellent tensile strength and toughness. The alloy contains chromium, nickel, and copper, contributing to its high corrosion resistance. Furthermore, it undergoes precipitation hardening after heat treatment, making it highly durable and resistant to wear and tear. Stainless steel 17-4ph angles also feature good machinability, making them easier to work.

Table Content

Stainless Steel 15-5ph Flats Corrosion Resistance

Stainless steel 15-5ph flats are another popular product made from this sought-after alloy. The 15-5ph alloy offers superior corrosion resistance compared to other stainless steel alloys. It contains chromium, nickel, and copper, contributing significantly to its anti-corrosive properties. In addition, the high amount of phosphorus in the alloy enhances its welding and fabricating capabilities. Stainless steel 15-5ph flats also resist stress cracking, making them ideal for heavy-duty applications.

Stainless Steel 17-4ph Angles Chemical Composition

The chemical composition of stainless steel at 17-4ph angles determines its properties. The alloy contains chromium, nickel, copper, and manganese, among other elements, which contribute to its high strength and durability. It also contains phosphorus, which enhances its welding and fabrication capabilities. The alloy's precipitation-hardening process increases its resistance to wear and corrosion, making it ideal for various mechanical and structural applications.

Stainless Steel 15-5ph Flats Applications

Stainless steel 15-5ph flats are widely used in applications requiring high strength, durability, and corrosion resistance. Some common uses of these flats include marine, aerospace, and automotive components, medical instruments, chemical processing equipment, and nuclear reactors. Due to their resistance to stress cracking, they are also used in heavy machinery and equipment like shafts, gears, and bearings.

Stainless Steel 17-4ph Angles Heat Treatment

Stainless steel 17-4ph angles undergo precipitation hardening after heat treatment, making them highly durable and resistant to wear and tear. The heat treatment process, known as solution annealing, involves heating the alloy to high temperatures and cooling it rapidly to enhance its mechanical properties. The alloy is then aged at lower temperatures to produce the desired properties. The heat treatment process also enhances the alloy's resistance to corrosion, making it ideal for use in harsh environments.

Molten Steel Casting

Laser Fused, Hot Rolled Or Cold Drawn

Desired Length Cutting

Testing & Finishing

| Specifications | ASTM A 276/A 276M,A 484/A 484M,A 564/A 564M,A 582/A582M,A 638 /A 638M,A705/A705M |

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Angle Sizes | 5mm to 9mm |

| Flat Sizes | 2mm ~ 100mm etc. |

| Thickness | 3.0mm – 120mm |

| Length | 3MTR, 4MTR, 5MTR, 6MTR or Custom Cut Sizes |

| Manufacturing Quality | Hot rolled (HR), Cold rolled (CR), Annealed, Forged, Heat Treated, Galvanized etc |

- 15-5PH Stainless Steel Angles Stock

- UNS S17400 Angles

- Stainless Steel 15-5PH Angle Price List

- 15-5PH Stainless Steel Forged Angle

- Stainless Steel 15-5PH Annealed Angles

- ASME SA484 Stainless Steel 15-5PH Angle

- SS 15-5PH Angle

- ASTM A276 Stainless Steel 15-5PH Angle

- Stainless Steel 17-4PH Industrial Angles

- 17-4PH Stainless Steel 90 Degree Angle

- SS 15-5PH Angles Price

- SS 15-5PH Unequal Angle

- Stainless Steel 17-4PH Heat Treated Angles

- 15-5PH Stainless Steel 'L' Shaped Angle

- Stainless Steel 15-5PH Hot rolled Angles

- Stainless Steel 1.4542 Angle

- SS 17-4PH Angle

- ASTM A484 Stainless Steel 15-5PH Angle

- 15-5ph Stainless Steel Cold Rolled Angles

- UNS S15500 Galvanized Angle

- ASME SA276 Stainless Steel 15-5PH Angle

- Stainless Steel 17-4PH Equal Angle

- Stainless Steel 1.4545 Angle

- Stainless Steel 15-5PH Flat Price List

- SS 15-5PH Flat

- 15-5PH Stainless Steel Flats Stock

- 17-4PH Stainless Steel Cold Drawn Flats

- Stainless Steel 17-4PH Industrial Flats

- UNS S17400 Flats

- SS 15-5PH Flats Price

- Stainless Steel 17-4PH Heat Treated Flats

- 15-5PH Stainless Steel Flat Rods

- Stainless Steel 17-4PH Patta

- SS 15-5PH Patti

- ASTM A484 Stainless Steel 15-5PH Flat

- Stainless Steel 15-5PH Annealed Flats

- SS 17-4Ph Flat

- 15-5PH Stainless Steel Cold Rolled Flats

- ASTM A276 Stainless Steel 15-5PH Flat

- 15-5PH Stainless Steel Forged Flat

- UNS S15500 Galvanized Flat

- Stainless Steel 1.4545 Flat

- Stainless Steel 1.4542 Flat

- ASME SA276 Stainless Steel 15-5PH Flat

- Stainless Steel 15-5PH Hot rolled Flats

- ASME SA484 Stainless Steel 15-5PH Flat

| STANDARD | WERKSTOFF NR. | UNS | JIS | AFNOR | EN |

| SS 15-5PH | 1.4545 | S15500 | - | - | - |

| SS 17-4PH | 1.4542 | S17400 | SUS 630 | Z6CNU17-04 | X5CrNiCuNb16.4 |

| Grade | C | Mn | Si | P | S | Cr | Mo | Cb+Ta |

| SS 15-5PH | .07 max | 1.0 max | 1.0 max | .04 max | .03 max | 15.5 - 14.0 | - | .45 - .15 |

| SS 17-4PH | 0.07 max | 1.0 max | 1.0 max | .07 max | .03 max | 17.5 - 15.0 | .05 | - |

| Grade | Ultimate Tensile Strength, psi | Yield Strength, psi | Elongation | Rockwell Hardness |

| 15-5PH | 161,000 | 140,000 | 7.6% | C35 |

| 17-4PH | 160,000 | 145,000 | 5% | C35 |

“ Check Bhansali Exports's offered stainless steel 15-5PH & 17-4PH angles Prices, flats Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”

Nepal, Israel, Bhutan, Egypt, Afghanistan, South Korea, Singapore, Kuwait, Taiwan, Macau, Maldives, Malaysia, India, Armenia, Iraq, Thailand, China, Saudi Arabia, Qatar, United Arab Emirates, Indonesia, Sri Lanka, British, Kyrgyzstan, Japan, Turkey, Russia, Bahrain, Myanmar, Azerbaijan, Jordan, Mongolia, Philippines, North Korea, Bangladesh, Lebanon, Hong Kong, Iran, Vietnam, Oman.

Turkey, Spain, Netherlands, Italy, Portugal, Denmark, Romania, Belgium, Czechia/Czech Republic, Azerbaijan, Luxembourg, Bulgaria, Monaco, Slovakia, Norway, Cyprus, Malta, Latvia, Ukraine, Germany, Lithuania, Austria, Serbia, Moldova, Liechtenstein, Ireland, Finland, France, Hungary, Russia, Poland, Switzerland, Croatia, Greece, Estonia, Belarus, Sweden, United Kingdom.

Mauritius, Zimbabwe, Uganda, Niger, Egypt, Madagascar, Burundi, Senegal, Libya, Namibia, Liberia, Nigeria, Ethiopia, Gambia, Eswatini, Zambia, Mozambique, Tunisia, Angola, Tanzania, Seychelles, Burkina Faso, Botswana, Mauritania, Algeria, Cameroon, Morocco, South Africa, Rwanda, Kenya, Central African Republic.

Cuba, Honduras, Mexico, Saint Vincent and the Grenadines, Dominican Republic, Bahamas, Guatemala, Costa Rica, Trinidad and Tobago, Antigua and Barbuda, Saint Lucia, El Salvador, Jamaica, Dominica, Haiti, United States of America, Canada, Grenada, Barbados, Nicaragua, Panama, Belize.

Ecuador, Solomon Islands, Argentina, Papua New Guinea, Vanuatu, Marshall Islands, Peru, New Zealand, Venezuela, Bolivia, Palau, Chile, Tuvalu, Brazil, Australia, Paraguay, Uruguay, Tonga, Guyana, Nauru, Suriname, Kiribati, Colombia, Fiji, Micronesia, Samoa.

Paris, Adelaide, Bremen, Batam, Khor Fakkan, Fujairah, Abdali, Bursa, Jayapura, Denpasar, Glasgow, Chelyabinsk, Dubai, Chennai, Bangalore, Banjarmasin, Al Ain, Trabzon, Salmiya, Düsseldorf, Sharjah, Abu Dhabi, Augsburg, Bordeaux, Hobart, Ruwais, Saint Petersburg, Lyon, Delhi, Bristol, Perth, Ottawa, Vancouver, Makassar, Marseille, Southampton, Mississauga, Lucknow, Edirne, Sydney, Al Ahmadi, Fethiye, Antalya, Ajman, Hatta, Mumbai, Medan, Toulouse, Fintas, Nice, Toronto, Mahboula, Birmingham, Kazan, Munich, Hamburg, Barnaul, Quebec City, Brisbane, Oxford, Fahaheel, Al Jahra, Melbourne, Brampton, Edinburgh, Lyon, Montreal, Lille, Ahmedabad, Ballarat, Konya, Krasnodar, Dresden, Manchester, Essen, Surabaya, Winnipeg, Mackay, Darwin, Izmir, Hyderabad, Novosibirsk, Newcastle upon Tyne, Saratov, Dortmund, Bhopal, Ghayathi, Bendigo, Omsk, Jabriya, Cologne, Sabah Al-Salem, Strasbourg, Ankara, Moscow, Liverpool, Bandung, Yogyakarta, Volgograd, Denizli, Istanbul, Berlin, Hawally, Hamilton, Navi Mumbai, London, Surrey, Jakarta, Kolkata, Rouen.