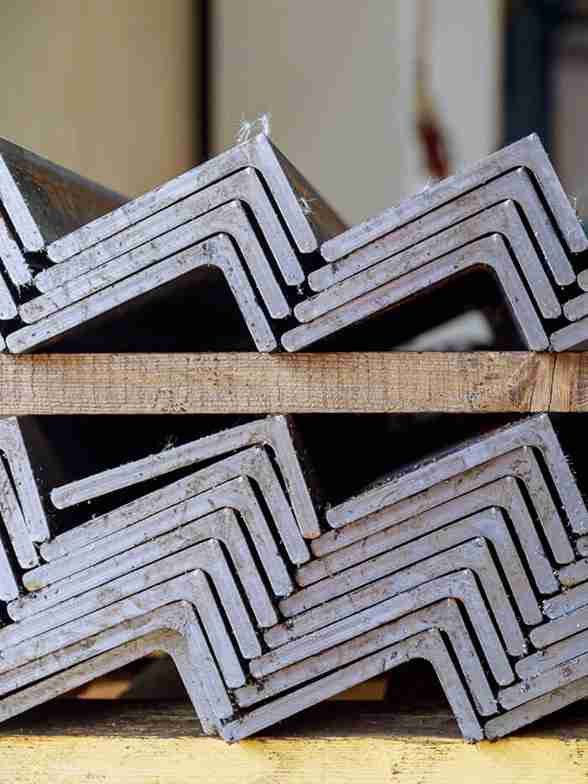

Nickel alloys are widely known for their superior resistance to corrosion and high-temperature durability, which makes them a popular choice across various industries. A particular nickel alloy that is highly versatile and sought after is Inconel 600/601 Angles & Flats. These angles and flats are known for their outstanding resistance to heat, oxidation, and corrosion in extreme environments.

Inconel 600 Angles Features:

Inconel 600 angles are non-magnetic, have high strength, excellent resistance to heat and corrosion, and are easy to fabricate. Other features of Inconel 600 angles include its resistance to alkaline solutions, chloride-ion stress corrosion, and oxidation at high temperatures. Furthermore, Inconel 600 angles retain their mechanical properties and flexibility even after prolonged exposure to high temperatures.

Table Content

Inconel 601 Flats Corrosion Resistance:

Inconel 601 flats are known for their excellent resistance to oxidation and scaling at high temperatures. Additionally, they are highly resistant to carburization, sulfur-bearing gases, and corrosive environments. Inconel 601 flats can also resist oxidation and scaling from nitriding atmospheres, making them suitable for applications in the aviation industry, notably for parts subjected to high-temperature operations such as exhaust systems.

Inconel 600 Angles Chemical Composition:

Inconel 600 angles have a unique chemical composition, which includes nickel and chromium as their primary components. It also contains varying percentages of iron, manganese, carbon, silicon, sulfur, copper, and phosphorus. The chemical composition of Inconel 600 angles gives them excellent corrosion resistance, high-temperature flexibility, and superior strength.

Inconel 601 Flats Applications:

Inconel 601 flats are used in the aerospace industry for their high-temperature resistance and excellent stress-corrosion cracking properties. They can also withstand high-pressure environments, making them suitable for oil and gas production, power generation, and chemical processing applications. Other common applications of Nickel Alloy Inconel 601 Flats include heat exchanger tubing, furnace muffles, and the support grids of electric heaters.

Inconel 600 Angles Machining:

Inconel 600 angles are easy to machine, but using the right cutting tool, including high-speed steel or carbide tools with a large rake angle, is essential. Additionally, to avoid work hardening, it is best to use slow speeds and heavy feed rates to machine Inconel 600 angles. It is also crucial to adjust the cutting tools frequently, ensure adequate coolant flow and use constant speeds while machining.

Molten Steel Casting

Laser Fused, Hot Rolled Or Cold Drawn

Desired Length Cutting

Testing & Finishing

| Specifications | ASTM B166 / ASME SB166 |

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Angle Sizes | 5mm to 9mm |

| Flat Sizes | 2mm ~ 100mm etc. |

| Thickness | 3.0mm – 120mm |

| Length | 3MTR, 4MTR, 5MTR, 6MTR or Custom Cut Sizes |

| Manufacturing Quality | Hot rolled (HR), Cold rolled (CR), Annealed, Forged, Heat Treated, Galvanized etc |

- 600 Inconel 'L' Shaped Angle

- ASTM B166 Inconel 600 Angle

- Inconel 2.4816 Angle

- Inconel 2.4851 Angle

- Inconel Alloy 600 Angles Price

- 600 Inconel Forged Angle

- Inconel Alloy 601 Heat Treated Angles

- Inconel Alloy 601 Angle

- ASME SB166 Inconel 601 Angle

- ASME SB166 Inconel 600 Angle

- UNS N06600 Galvanized Angle

- Inconel Alloy 600 Unequal Angle

- Alloy 600 Hot rolled Angles

- UNS N06601 Angles

- 600 Inconel Angles Stock

- 601 Inconel 90 Degree Angle

- ASTM B166 Inconel 601 Angle

- Alloy 601 Equal Angle

- Nickel Alloy 600 Cold Rolled Angles

- Inconel Alloy 600 Angle

- Inconel 601 Industrial Angles

- Inconel 600 Annealed Angles

- Inconel 600 Angle Price List

- ASME SB166 Inconel 600 Flat

- 600 Inconel Flat Rods

- Inconel 600 Flat Price List

- 600 Inconel Flats Stock

- UNS N06601 Flats

- ASTM B166 Inconel 601 Flat

- Inconel Alloy 600 Flat

- Alloy 601 Industrial Flats

- 601 Inconel Cold Drawn Flats

- ASME SB166 Inconel 601 Flat

- 600 Inconel Cold Rolled Flats

- ASTM B166 Inconel 600 Flat

- Inconel Alloy 601 Flat

- Inconel 600 Annealed Flats

- Inconel 2.4851 Flat

- Nickel Alloy 600 Patti

- UNS N06600 Galvanized Flat

- Inconel 601 Patta

- Inconel 2.4816 Flat

- 600 Inconel Forged Flat

- Inconel Alloy 600 Flats Price

- Alloy 600 Hot rolled Flats

- Inconel 601 Heat Treated Flats

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 600 | 2.4816 | N06600 | NCF 600 | NA 13 | МНЖМц 28-2,5-1,5 | NC15FE11M | NiCr15Fe |

| Inconel 601 | 2.4851 | N06601 | NCF 601 | NA 49 | XH60BT | NC23FeA | NiCr23Fe |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 600 | 0.15 max | 1.00 max | 0.50 max | 0.015max | 0.50 max | 6.00 – 10.00 | 72.00 min | 14.00 – 17.00 |

| Inconel 601 | 0.10 max | 1 max | 0.50 max | 0.15 min | 1 max | balance | 58.0-63.0 | 21.0–25.0 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 600 | 8.47 g/cm3 | 1413 °C (2580 °F) | Psi – 95,000 , MPa – 655 | Psi – 45,000 , MPa – 310 | 40 % |

| Inconel 600 | 8.1 g/cm3 | 1411 °C (2571 °F) | Psi – 80,000 , MPa – 550 | Psi – 30,000 , MPa – 205 | 30 % |

“ Check Bhansali Exports's offered inconel alloy 600 & 601 angles prices, flats Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”

Indonesia, Malaysia, Iraq, North Korea, Macau, Oman, Hong Kong, Sri Lanka, Bhutan, Russia, Afghanistan, Bahrain, Lebanon, Azerbaijan, Israel, Japan, Saudi Arabia, British, Kyrgyzstan, South Korea, Kuwait, Armenia, China, Vietnam, Egypt, Qatar, Nepal, Singapore, Jordan, Turkey, Mongolia, Iran, Bangladesh, India, Thailand, United Arab Emirates, Maldives, Myanmar, Taiwan, Philippines.

Bulgaria, France, Liechtenstein, Sweden, Netherlands, Latvia, Cyprus, Monaco, Finland, Ireland, Azerbaijan, Romania, Italy, United Kingdom, Greece, Poland, Ukraine, Belarus, Austria, Luxembourg, Belgium, Serbia, Switzerland, Germany, Hungary, Spain, Slovakia, Russia, Malta, Lithuania, Croatia, Norway, Czechia/Czech Republic, Moldova, Portugal, Turkey, Denmark, Estonia.

Namibia, Zambia, Cameroon, Mozambique, Egypt, Seychelles, Kenya, Burundi, Tunisia, Madagascar, Ethiopia, Algeria, Tanzania, Mauritius, Burkina Faso, Libya, Gambia, Eswatini, Uganda, Liberia, Mauritania, South Africa, Central African Republic, Rwanda, Zimbabwe, Niger, Morocco, Botswana, Senegal, Angola, Nigeria.

Saint Lucia, Antigua and Barbuda, Panama, Mexico, Grenada, Barbados, Belize, Honduras, El Salvador, Bahamas, United States of America, Haiti, Nicaragua, Guatemala, Dominican Republic, Dominica, Costa Rica, Cuba, Canada, Jamaica, Trinidad and Tobago, Saint Vincent and the Grenadines.

Tuvalu, Guyana, Samoa, Paraguay, Bolivia, Fiji, Palau, Argentina, Tonga, Venezuela, Vanuatu, Solomon Islands, Uruguay, Brazil, Nauru, Peru, Ecuador, Marshall Islands, Micronesia, Suriname, New Zealand, Colombia, Australia, Kiribati, Chile, Papua New Guinea.

Birmingham, Bristol, Dubai, Bremen, Quebec City, Hawally, Bhopal, Hamilton, Hamburg, Kolkata, Fethiye, Cologne, Perth, Bendigo, Montreal, Lyon, Yogyakarta, Düsseldorf, Novosibirsk, Medan, Mumbai, Omsk, Lille, Trabzon, Southampton, Ghayathi, Brisbane, Melbourne, Saratov, Salmiya, Kazan, Newcastle upon Tyne, Istanbul, Bursa, Abdali, Toronto, Chelyabinsk, Rouen, Sydney, Moscow, Darwin, Hyderabad, Liverpool, Lucknow, Dortmund, Krasnodar, Makassar, Toulouse, Antalya, Essen, London, Surrey, Saint Petersburg, Augsburg, Bangalore, Delhi, Ankara, Hatta, Denizli, Al Ain, Fahaheel, Bandung, Vancouver, Munich, Denpasar, Khor Fakkan, Lyon, Izmir, Hobart, Marseille, Winnipeg, Ottawa, Strasbourg, Al Ahmadi, Surabaya, Berlin, Paris, Ruwais, Jabriya, Volgograd, Jakarta, Sharjah, Bordeaux, Nice, Edinburgh, Navi Mumbai, Adelaide, Abu Dhabi, Mississauga, Sabah Al-Salem, Glasgow, Banjarmasin, Edirne, Dresden, Barnaul, Chennai, Konya, Fujairah, Batam, Manchester, Ballarat, Ajman, Mackay, Jayapura, Oxford, Brampton, Al Jahra, Ahmedabad, Mahboula, Fintas.