Nickel alloys are known for their strength, durability, and resistance to high temperatures and corrosion. One such alloy is Inconel 625, widely used in the aerospace, marine, chemical, and oil and gas industries. Inconel 625 angle bars and flats are two forms of this versatile alloy regularly used in various applications. Inconel 625 angles and flats are among the most versatile and durable nickel alloys. Their unique combination of strength, stability, corrosion resistance, and machinability make them ideal for use in a wide range of applications across various industries.

Inconel 625 Angle Features

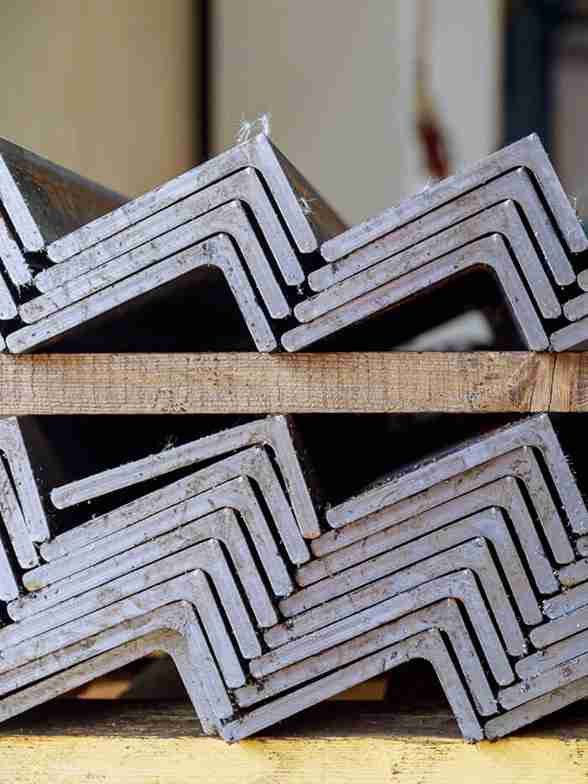

Inconel 625 angles are known for their exceptional strength and stability under high-temperature conditions. With a chromium-nickel-molybdenum composition, these angles exhibit high corrosion resistance, making them ideal for use in environments with saltwater or acidic solutions. The flexibility and versatility of these angles enable them to be easily machined to any required shape, making them fit for use in complex designs where strength, durability, and aesthetic appeal are necessary.

Table Content

Inconel 625 Flats Corrosion Resistance

Apart from the strength and stability of Inconel 625 flats, these alloys are also highly corrosion-resistant. With a combination of nickel, chromium, molybdenum, and niobium composition, these flats offer excellent corrosion resistance, even in extreme high-pressure and high-temperature environments. They are ideal for chemical processing, aerospace, marine, and oil and gas industries.

Inconel 625 Angles Chemical Composition

High amounts of nickel, chromium, molybdenum, and niobium characterize the chemical composition of Inconel 625 angles. These elements give the alloy exceptional strength and resistance to high temperatures and corrosion. The high level of nickel in the alloy enables it to maintain its toughness even at cryogenic temperatures. Moreover, the alloy's low carbon content enhances its weldability and resistance to cracking.

Inconel 625 Flats Applications

Inconel 625 flats are widely employed in the aerospace, marine, and oil and gas industries. In these applications, the flats must withstand high mechanical and thermal stresses and prolonged corrosive environments. With their unique properties, Inconel 625 flats can withstand harsh and extreme conditions, making them ideal for use in equipment such as pressure vessels, heat exchangers, and combustion chambers.

Inconel 625 Angles Machining

Inconel 625 angles can be machined using various techniques, including drilling, milling, and turning. Its high strength enables it to resist deformation during machining, while its low thermal conductivity helps to eliminate thermal deformation. Moreover, while Inconel 625 angles tend to harden during machining due to its high nickel content, the appropriate tool selection and cutting parameters enable it to be precisely machined to achieve the desired shape and size.

Molten Steel Casting

Laser Fused, Hot Rolled Or Cold Drawn

Desired Length Cutting

Testing & Finishing

| Specifications | ASTM B446 / ASME SB446 |

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Angle Sizes | 5mm to 9mm |

| Flat Sizes | 2mm ~ 100mm etc. |

| Thickness | 3.0mm – 120mm |

| Length | 3MTR, 4MTR, 5MTR, 6MTR or Custom Cut Sizes |

| Manufacturing Quality | Hot rolled (HR), Cold rolled (CR), Annealed, Forged, Heat Treated, Galvanized etc |

- 625 Inconel Angles Stock

- ASTM B446 Inconel 625 Angle

- ASTM B446 Inconel 625 Angle

- Inconel 2.4856 Angle

- 625 Inconel 90 Degree Angle

- Inconel 625 Angle Price List

- Alloy 625 Hot rolled Angles

- ASME SB446 Inconel 625 Angle

- Inconel Alloy 625 Angles Price

- Inconel Alloy 625 Angle

- UNS N06625 Angles

- ASME SB446 Inconel 625 Angle

- Nickel Alloy 625 Cold Rolled Angles

- Inconel Alloy 625 Unequal Angle

- 625 Inconel Forged Angle

- Alloy 625 Equal Angle

- Inconel Alloy 625 Heat Treated Angles

- 625 Inconel 'L' Shaped Angle

- UNS N06625 Galvanized Angle

- Inconel 625 Industrial Angles

- Inconel 625 Annealed Angles

- Inconel 625 Annealed Flats

- ASME SB446 Inconel 625 Flat

- 625 Inconel Cold Drawn Flats

- UNS N06625 Galvanized Flat

- Alloy 625 Industrial Flats

- Inconel Alloy 625 Flat

- ASTM B446 Inconel 625 Flat

- ASME SB446 Inconel 625 Flat

- 625 Inconel Flats Stock

- Inconel 625 Flat Price List

- Inconel 2.4856 Flat

- ASTM B446 Inconel 625 Flat

- 625 Inconel Cold Rolled Flats

- Inconel 625 Heat Treated Flats

- Alloy 625 Hot rolled Flats

- Inconel Alloy 625 Flats Price

- 625 Inconel Flat Rods

- UNS N06625 Flats

- 625 Inconel Forged Flat

- Nickel Alloy 625 Patti

- Inconel 625 Patta

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| Inconel 625 | 2.4856 | N06625 | NCF 625 | NA 21 | ХН75МБТЮ | NC22DNB4M | NiCr22Mo9Nb |

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr |

| Inconel 625 | 0.10 max | 0.50 max | 0.50 max | 0.015 max | - | 5.0 max | 58.0 min | 20.0 - 23.0 |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 625 | 8.4 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000 , MPa – 930 | Psi – 75,000 , MPa – 517 | 42.5 % |

“ Check Bhansali Exports's offered inconel alloy 625 angles prices, flats Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”

United Arab Emirates, Macau, Azerbaijan, Vietnam, Oman, Bhutan, Indonesia, Armenia, Thailand, Jordan, India, Maldives, South Korea, Israel, Iraq, Bahrain, China, Taiwan, Hong Kong, Iran, Sri Lanka, Kyrgyzstan, Egypt, Qatar, Bangladesh, Japan, Malaysia, Lebanon, Mongolia, Saudi Arabia, Russia, Philippines, Singapore, Kuwait, Myanmar, Nepal, British, North Korea, Afghanistan, Turkey.

Germany, Latvia, Azerbaijan, United Kingdom, Cyprus, Belgium, France, Czechia/Czech Republic, Romania, Croatia, Portugal, Turkey, Netherlands, Bulgaria, Sweden, Ireland, Austria, Luxembourg, Spain, Moldova, Denmark, Poland, Lithuania, Liechtenstein, Finland, Malta, Switzerland, Ukraine, Serbia, Russia, Norway, Slovakia, Belarus, Monaco, Italy, Estonia, Greece, Hungary.

Morocco, South Africa, Liberia, Gambia, Mozambique, Zambia, Burkina Faso, Mauritius, Senegal, Uganda, Rwanda, Nigeria, Kenya, Angola, Central African Republic, Eswatini, Zimbabwe, Ethiopia, Namibia, Libya, Niger, Cameroon, Mauritania, Algeria, Botswana, Egypt, Tanzania, Seychelles, Tunisia, Burundi, Madagascar.

El Salvador, Belize, Costa Rica, Barbados, Trinidad and Tobago, Jamaica, Mexico, Honduras, Panama, Grenada, United States of America, Dominica, Nicaragua, Haiti, Cuba, Antigua and Barbuda, Saint Vincent and the Grenadines, Dominican Republic, Bahamas, Guatemala, Saint Lucia, Canada.

Paraguay, Tuvalu, Chile, Uruguay, Marshall Islands, Bolivia, Ecuador, Papua New Guinea, Colombia, New Zealand, Suriname, Argentina, Micronesia, Venezuela, Samoa, Palau, Tonga, Solomon Islands, Vanuatu, Nauru, Brazil, Peru, Kiribati, Guyana, Australia, Fiji.

Ghayathi, Hobart, Volgograd, Al Jahra, Hawally, Al Ain, Paris, Omsk, Melbourne, Brampton, Barnaul, Bhopal, Delhi, Cologne, Winnipeg, Chelyabinsk, Fujairah, Dresden, Sabah Al-Salem, Ankara, Rouen, Ottawa, Abu Dhabi, Al Ahmadi, Jabriya, Augsburg, Sharjah, Hatta, Mumbai, Batam, Trabzon, Bandung, Krasnodar, Quebec City, Surrey, Bristol, Toronto, Perth, Istanbul, Lucknow, Moscow, Khor Fakkan, Manchester, Lyon, Montreal, Oxford, Bangalore, Banjarmasin, Berlin, Birmingham, Glasgow, Darwin, Ballarat, Hyderabad, Strasbourg, Dubai, Mackay, Bursa, Chennai, Adelaide, Navi Mumbai, Saint Petersburg, Marseille, Antalya, Jakarta, Salmiya, Lille, Ruwais, Bordeaux, Liverpool, Novosibirsk, Lyon, Izmir, Sydney, Mahboula, Surabaya, Fintas, Southampton, Düsseldorf, Abdali, Konya, Dortmund, Ajman, Saratov, Munich, Denpasar, Medan, Fethiye, Kazan, Fahaheel, Toulouse, Bendigo, Bremen, Kolkata, Vancouver, Denizli, Edirne, Essen, Ahmedabad, Yogyakarta, Hamburg, Edinburgh, Mississauga, Jayapura, Newcastle upon Tyne, Nice, Makassar, London, Hamilton, Brisbane.