Nickel alloys are known for their high-temperature resistance, excellent corrosion resistance, and high strength, even at elevated temperatures. One such versatile nickel alloy is Nimonic 80, which is used in a wide range of applications and industries. Nimonic 80 combines nickel, chromium, iron, and small amounts of other elements like titanium, carbon, aluminum, and silicon.

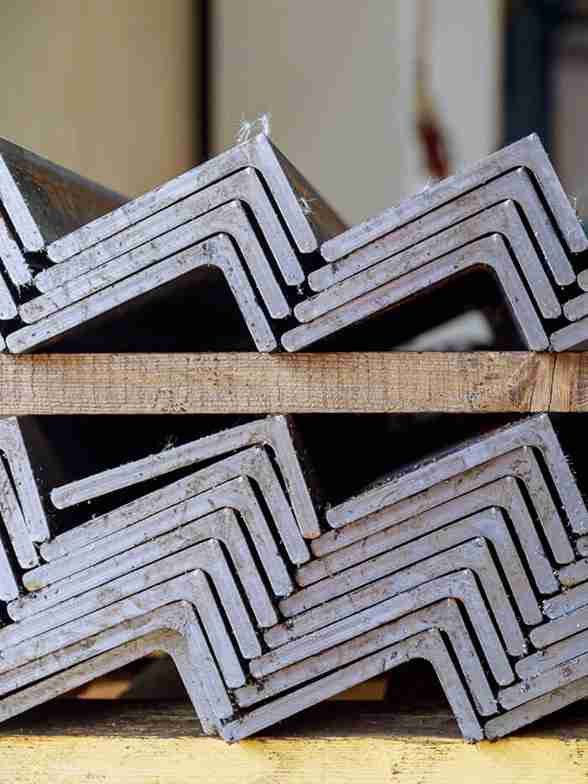

Nimonic 80 Angles Features:

Nimonic 80 angles are a popular choice in industries requiring high-temperature resistance. The angles are known for their excellent mechanical properties, including high strength and toughness, even at elevated temperatures. Nimonic 80 angles are easy to weld and offer excellent resistance to oxidation and corrosion in acidic environments. The angles exhibit good creep resistance and maintain mechanical properties even at temperatures above 815°C.

Table Content

Nimonic 80 Flats Corrosion Resistance:

Nimonic 80 flats offer excellent corrosion resistance, especially in environments rich in sulfur. The flats exhibit good resistance to pitting, crevice corrosion, and oxidation, even in alkaline environments. Nimonic 80 flats offer excellent resistance to high-temperature oxidation and thermal cycling, making them an ideal choice for applications that require high-temperature resistance.

Nimonic 80 Angles Chemical Composition:

Nimonic 80 angles combine nickel, chromium, iron, and small titanium, carbon, aluminium, and silicon additions. The chemical composition of Nimonic 80 angles is designed to offer high-temperature resistance, strength, and excellent mechanical properties. The addition of titanium enhances the alloys' ageing properties, while carbon and silicon improve their oxidation resistance.

Nimonic 80 Flats Applications:

Nimonic 80 flats find many applications in aerospace, power generation, and chemical processing industries. The flats are commonly used in gas turbine parts, heat exchangers, valves, and turbochargers. Due to their high-temperature resistance and excellent corrosion resistance, Nimonic 80 flats are commonly used in high-stress applications where conventional alloys would fail.

Nimonic 80 Angles Heat Treatment:

Nimonic 80 angles can be heat-treated to enhance their mechanical properties. The heat treatment involves annealing the angles at 1080-1120°C, followed by air cooling or quenching in water. Solution annealing ensures that the angles' structure is homogenized and any carbides that may have formed during processing or welding are dissolved. After solution annealing, the angles are aged at 800-850°C for 4-16 hours to obtain a strengthening effect while retaining their flexibility.

Molten Steel Casting

Laser Fused, Hot Rolled Or Cold Drawn

Desired Length Cutting

Testing & Finishing

| Specifications | ASTM B637, ASME SB637 |

| Dimension Standard | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Angle Sizes | 5mm to 9mm |

| Flat Sizes | 2mm ~ 100mm etc. |

| Thickness | 3.0mm – 120mm |

| Length | 3MTR, 4MTR, 5MTR, 6MTR or Custom Cut Sizes |

| Manufacturing Quality | Hot rolled (HR), Cold rolled (CR), Annealed, Forged, Heat Treated, Galvanized etc |

- ASTM B637 Nimonic 80A Angle

- NIMONIC Alloy 80A Cold Rolled Angles

- Nimonic 80a Angles Stock

- NIMONIC Alloy 80a Hot rolled Angles

- Nimonic 80A Angle

- Nickel Alloy 80a Annealed Angles

- UNS N07080 Galvanized Angle

- Nimonic 80A Industrial Angles

- 2.4631 Angle

- Super Alloy Nimonic 80A 'L' Shaped Angle

- NIMONIC Alloy 80A Unequal Angle

- Nimonic 80A Angle Price List

- Nimonic 80A 90 Degree Angle

- ASTM B637 Nimonic 80a Angle

- ASME SB637 Nimonic 80A Angle

- Nimonic 80A Heat Treated Angles

- Super Alloy Nimonic 80A Forged Angle

- UNS N07080 Angles

- Nimonic 80A Angles Price

- NIMONIC Alloy 80A Equal Angle

- ASME SB637 Super Alloy Nimonic 80A Angle

- Nimonic 80A Flat

- ASME SB637 Nimonic 80A Flat

- Nimonic 80A Annealed Flats

- Super Alloy Nimonic 80A Cold Drawn Flats

- NIMONIC Alloy 80a Flat Rods

- Nimonic 80A Heat Treated Flats

- Super Alloy Nimonic 80A Cold Rolled Flats

- Nimonic 80A Patta

- Nimonic 80A Patti

- Nimonic 80a Forged Flat

- UNS N07080 Galvanized Flat

- Nickel Alloy 80a Industrial Flats

- NIMONIC Alloy 80A Flat Price List

- 2.4631 Flat

- UNS N07080 Flats

- ASME SB637 Nimonic 80A Flat

- Super Alloy Nimonic 80A Hot rolled Flats

- NIMONIC Alloy 80a Flats Stock

- ASTM B637 Nimonic 80A Flat

- Nimonic 80A Flats Price

- ASTM B637 Nimonic 80A Flat

| STANDARD | WERKSTOFF NR. | UNS |

| Nimonic 80A | 2.4631 | N07080 |

| Grade | Ni | Cr | Fe | Co | Ti | Al |

| Nimonic 80A | 69 | 18-21 | 3 | 2 | 1.8-2.7 | 1.0-1.8 |

| Element | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Nimonic 80A | 8.19 g/cm3 | ksi – 181, MPa – 1250 | ksi – 113, MPa – 780 | 30 % |

“ Check Bhansali Exports's offered Nimonic 80A angles Prices, flats Dimensions & Weight. Place an order or enquire about your requirements. We will glad to be service. ”

South Korea, China, Nepal, Jordan, United Arab Emirates, North Korea, Russia, India, British, Afghanistan, Bahrain, Saudi Arabia, Bangladesh, Israel, Iran, Malaysia, Mongolia, Azerbaijan, Lebanon, Japan, Oman, Kuwait, Thailand, Macau, Myanmar, Bhutan, Egypt, Kyrgyzstan, Singapore, Vietnam, Sri Lanka, Indonesia, Philippines, Iraq, Armenia, Qatar, Taiwan, Maldives, Turkey, Hong Kong.

Netherlands, Malta, Norway, Luxembourg, Belgium, Moldova, Liechtenstein, Ireland, Portugal, Slovakia, Latvia, Germany, Finland, Spain, Russia, Belarus, Monaco, Switzerland, Serbia, Cyprus, France, Turkey, Hungary, United Kingdom, Italy, Azerbaijan, Croatia, Austria, Bulgaria, Ukraine, Denmark, Estonia, Poland, Greece, Sweden, Lithuania, Czechia/Czech Republic, Romania.

Mozambique, Burundi, Tanzania, Central African Republic, Ethiopia, Cameroon, Eswatini, Algeria, Mauritius, Burkina Faso, Morocco, Namibia, Seychelles, Botswana, Uganda, Kenya, Angola, Gambia, Libya, Zambia, Rwanda, Madagascar, Liberia, South Africa, Egypt, Senegal, Nigeria, Niger, Tunisia, Zimbabwe, Mauritania.

Belize, Dominican Republic, Bahamas, Haiti, Saint Vincent and the Grenadines, Saint Lucia, Nicaragua, Dominica, Antigua and Barbuda, United States of America, Barbados, Panama, Grenada, Jamaica, Canada, Mexico, Trinidad and Tobago, Honduras, Cuba, Guatemala, Costa Rica, El Salvador.

Fiji, Guyana, New Zealand, Argentina, Colombia, Bolivia, Australia, Micronesia, Vanuatu, Solomon Islands, Venezuela, Brazil, Chile, Uruguay, Palau, Peru, Tuvalu, Tonga, Papua New Guinea, Nauru, Ecuador, Suriname, Kiribati, Paraguay, Marshall Islands, Samoa.

Rouen, Berlin, Munich, Kazan, London, Strasbourg, Oxford, Volgograd, Trabzon, Bangalore, Mahboula, Konya, Dubai, Fujairah, Makassar, Al Ahmadi, Fethiye, Saint Petersburg, Edirne, Hobart, Mumbai, Fahaheel, Essen, Mackay, Hamilton, Saratov, Ajman, Surabaya, Dortmund, Lyon, Ahmedabad, Toronto, Düsseldorf, Brisbane, Paris, Bristol, Sabah Al-Salem, Ballarat, Melbourne, Antalya, Ankara, Bordeaux, Jakarta, Fintas, Ghayathi, Lyon, Chelyabinsk, Sydney, Izmir, Banjarmasin, Edinburgh, Kolkata, Ottawa, Al Jahra, Manchester, Vancouver, Toulouse, Al Ain, Southampton, Chennai, Bendigo, Lille, Nice, Bandung, Liverpool, Birmingham, Hatta, Hyderabad, Delhi, Denizli, Winnipeg, Lucknow, Marseille, Krasnodar, Salmiya, Augsburg, Barnaul, Medan, Abdali, Ruwais, Bhopal, Istanbul, Jayapura, Glasgow, Darwin, Novosibirsk, Surrey, Adelaide, Mississauga, Hawally, Batam, Newcastle upon Tyne, Navi Mumbai, Dresden, Quebec City, Perth, Bursa, Montreal, Jabriya, Sharjah, Khor Fakkan, Omsk, Brampton, Yogyakarta, Hamburg, Bremen, Denpasar, Cologne, Moscow, Abu Dhabi.