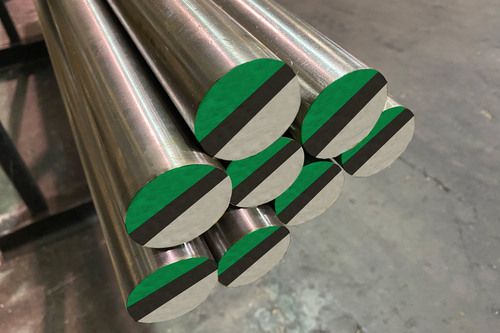

Stainless steel round bars are critical components in numerous industries, as much as they appear simple. Ranging from construction and automotive components to medical tools and food handling, the bars are highly prized for their strength, resistance to corrosion and versatility.

In this blog we will look at what stainless steel round bars are, how they are produced, the various types, the advantages and the industries they are used by.

What are Stainless Steel Round Bars?

Stainless steel round bars are the long, cylindrical rods of a round cross section made of an alloy that is mostly iron, chromium, nickel and other metals such as molybdenum and manganese. The corrosion resistant property is highly done by the presence of chromium content over 10.5%.

Offered in different grades, sizes and finishes, stainless steel round bars find application across machinery, construction, automotive, medical and food industries because of their superior mechanical properties like tensile strength, toughness and resistance to heat.

The Manufacturing Process of Stainless Steel Round Bars

1. Raw Material Selection and Melting

The method starts with the correct raw materials: iron, chromium, nickel, and other alloying material. These are combined in an electric arc furnace (EAF) which gets up to over 1600°C (2900°F) to create a homogeneous melt.Once melted the metal is casted into molds to make steel billets which are the beginning of the shape of the bars.

2. Billet Heating and Rolling

The cooled billets are heated to temperatures ranging from 1100°C to 1200°C (2000°F to 2200°F) to soften the steel and make it malleable. Billets are then sent through a rolling mill, which shapes them slowly into round bars in a succession of rollers. Hot rolling gives uniform diameter and removes cracks or voids.

At times, the bars are then further treated through cold drawing, in which the bars are drawn through a die under room temperature to define the dimensions and enhance surface smoothness.

3. Heat Treatment (Annealing)

The heat treatment of bars is carried out to relieve internal stresses induced into the product during rolling operations. Annealing is done by heating the bars at a predetermined temperature and slowly cooling them; this will soften the steel so that it is machine-friendly and less likely to crack when stressed. It also improves corrosion resistance by minimizing carbide formation.

4. Straightening

The bars tend to bend or warp after heat treatment. There is a straightening machine that utilizes rollers to remove any bends and have the bars straight and with very precise measurements. This is particularly important for industries like aerospace and automotive where high precision is critical.

5. Surface Finishing: Peeling, Grinding and Polishing

Surface finishing involves a number of steps to improve the look and usability of the bars. Treatments commonly applied are:

- Peeling: The surface layer is stripped away to remove such flaws as scale and rust allowing a smooth finish.

- Grinding: Once peeled, the bars are ground to smooth out any rough spots further providing them with a finer finish, and guaranteed dimensions.

- Polishing: For some sectors such as food processing or medical equipment, polishing is carried out to obtain a shiny, reflective surface that satisfies hygiene and beauty requirements.

6. Cutting to Length

The long stainless steel round bars are then cut to specified lengths. Depending on customer requirements, it is accomplished through saws, shears, or even lasers. Precise cutting ensures that the bars have length specifications for their ultimate use.

7. Inspection and Testing

Before shipment, the bars undergo several tests to ensure they meet quality standards. Common tests include:

- Visual examination for surface flaws like crack or staining.

- Mechanical testing to determine tensile strength, hardness and elongation.

- Chemical testing to verify that the composition of the alloy meets the specified requirements.

Types of Stainless Steel Round Bars

1. 304 Stainless Steel Bar

304 stainless steel is the most popular grade of stainless steel round bars. It is strongly resistant to corrosion and finds applications in numerous fields, such as food processing, medical devices and kitchen appliances.

2. 316 Stainless Steel Bar

316 stainless steel is equivalent to 304 but has molybdenum, which provides it with enhanced corrosion resistance, particularly in marine conditions. This grade is commonly applied for marine gear, chemical processing and other applications where the material will be exposed to aggressive chemicals or sea water.

3. 303 Stainless Steel Bar

This is a free-machining grade, i.e., Stainless Steel 303 Round Bars can be machined more easily compared to other grades. It’s frequently utilized in the manufacture of fasteners, bolts, nuts and screws.

4. 410 Stainless Steel Bar

410 stainless steel is a martensitic steel with good wear resistance and high strength. It is generally used in knives and tools, and wherever hardness is needed.

5. 416 Stainless Steel Bar

416 stainless steel is another stress-free machining grade, best for applications that need close tolerances. It is often utilized in shafts, pins and other components where accuracy is a important.

Advantages and Applications of Stainless Steel Round Bars

- Corrosion Resistance: The capacity of stainless steel to withstand corrosion and rust allows it to be used in outdoor, marine, and chemical environment.

- High Strength: Stainless steel bars are highly resistant and are capable of supporting heavy loads without cracking or breaking.

- Heat Resistance: They can resist high heat, thus being suitable for automotive and aerospace industries.

- Longevity: Stainless steel round bars possess a long lifespan minimizing the need for repeated replacement.

- Easy to Clean: Stainless steel’s lack of pores allows for easy cleaning, which is important in applications such as food processing and healthcare.

- Recyclability: Stainless steel is 100% recyclable making it an environmentally friendly material.

Applications include:

- Construction: Used for structural components such as beams, reinforcement bars, and supports.

- Automotive: The usual applications are axles, shafts and engine parts.

- Machinery: Used for tools, fasteners and parts subjected to heavy use.

- Medical: Equipment for surgeries, implants, and hospital equipment.

- Food Industry: Kitchen utensils, food processing machineries and storage tanks.

- Marine: Ship building and marine hardware.

Conclusion

Stainless steel round bars serve a wide array of industries where strength, durability and corrosion resistance make them essentially valuable in many applications. Understanding the processing turns out to be very revealing about the number of complex steps involved in developing such versatile bars-from melting and rolling to heat treatment and surface finishing. Due to their long life cycle, strength and versatility, these stainless steel round bars still constitute one of the core materials across worldwide industries.